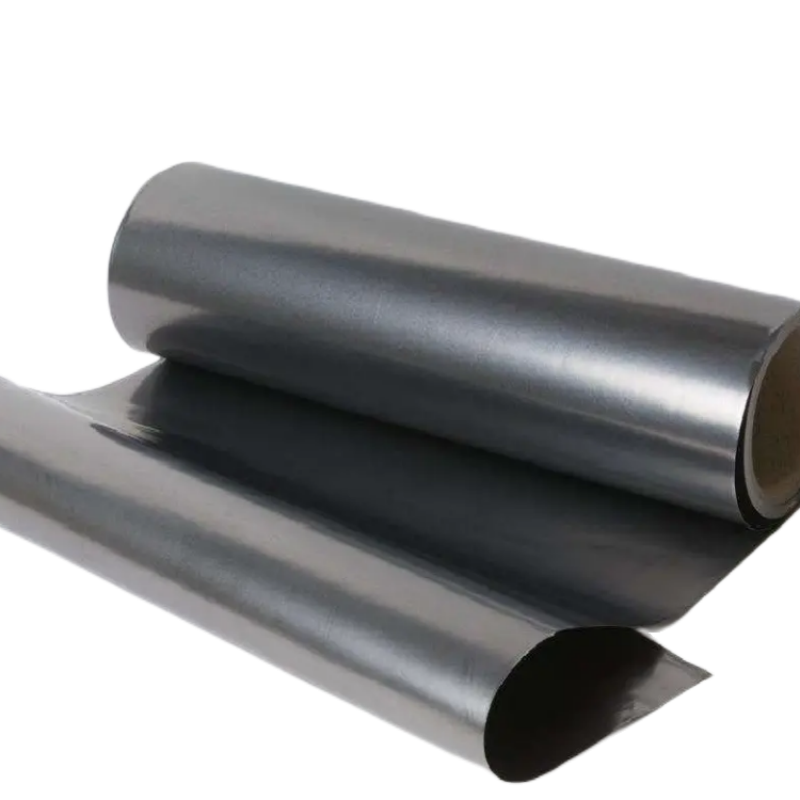

Thermal Conduction Principles of Graphite Paper in Modern Systems The primary function of graphite paper in thermal management systems is to facilitate the rapid movement of heat away from sensitive electronic components. Due to the unique hexagonal...

VIEW MORE

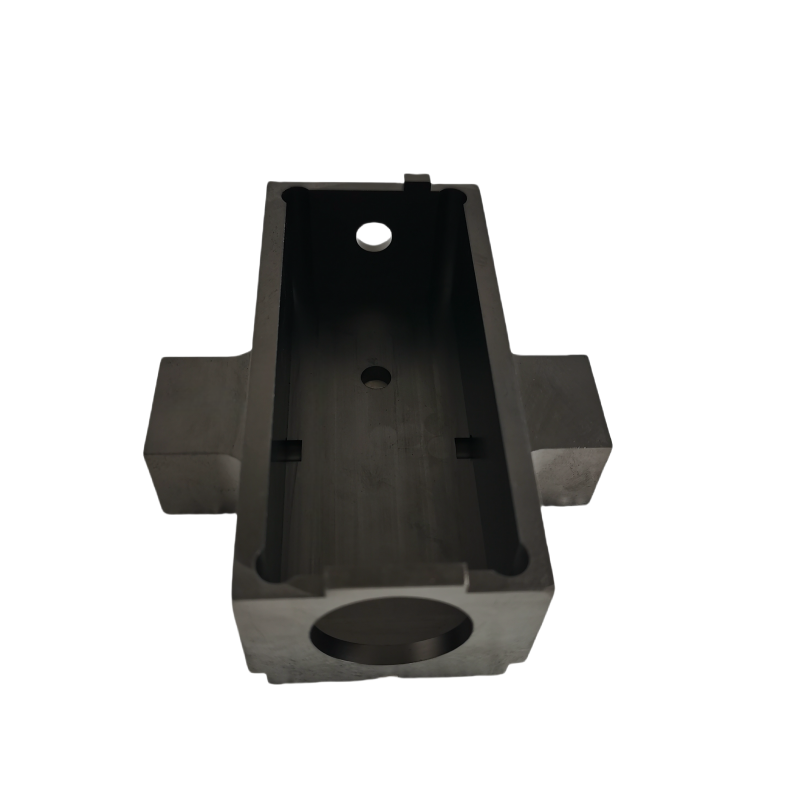

Factors Influencing Precision in the Graphite Mold Casting Process Precision casting relies heavily on the physical and chemical stability of the molding material used during the solidification of molten metal. When using a graphite mold, the primar...

VIEW MORE

What Makes Graphite Molds Ideal for High-Temperature Applications The selection of tooling materials for thermal processing determines the boundary between manufacturing success and catastrophic failure. In the realm of high-heat environments, the gr...

VIEW MORE

How Are Graphite Molds Used in Precision Casting and Melting The integration of advanced materials in industrial manufacturing has revolutionized the way we approach high-temperature metallurgical processes. Among these materials, the graphite mold s...

VIEW MORE

Impact of Graphite Heater Performance on Manufacturing Precision In high-temperature industrial environments, the pursuit of process accuracy often hinges on the thermal stability of the heating elements used within the system. A graphite heater ser...

VIEW MORE

Industrial heating applications demand materials that can withstand extreme temperatures while maintaining exceptional thermal conductivity and chemical resistance. Graphite heaters have emerged as a critical component across numerous manufacturing s...

VIEW MORE

In today's demanding industrial landscape, achieving precise temperature control while maintaining energy efficiency has become a critical factor for manufacturing success. Graphite heaters have emerged as a superior heating solution, offering except...

VIEW MORE

Vacuum furnace technology has revolutionized high-temperature processing across numerous industrial applications, from aerospace component manufacturing to semiconductor production. At the heart of these sophisticated systems lies the heating element...

VIEW MORE

Manufacturing industries across the globe rely on sealing solutions that can withstand extreme conditions while maintaining operational integrity. Among the most versatile and reliable sealing materials available today are graphite gaskets, which hav...

VIEW MORE

Industrial sealing solutions have evolved significantly over the past decades, with flexible graphite gaskets emerging as one of the most reliable and versatile options for critical applications. These advanced sealing components offer exceptional pe...

VIEW MORE

Understanding the Fundamental Distinctions Between Natural and Synthetic Graphite Materials In the world of industrial materials, graphite flakes play a crucial role across numerous applications, from energy storage to lubricants and beyond. The dist...

VIEW MORE

Understanding the Versatile Nature of Industrial Graphite Flakes The industrial world has long recognized graphite flake as a cornerstone material in various applications, particularly in lubricants and protective coatings. This naturally occurring f...

VIEW MORE