Understanding the Fundamental Distinctions Between Natural and Synthetic Graphite Materials

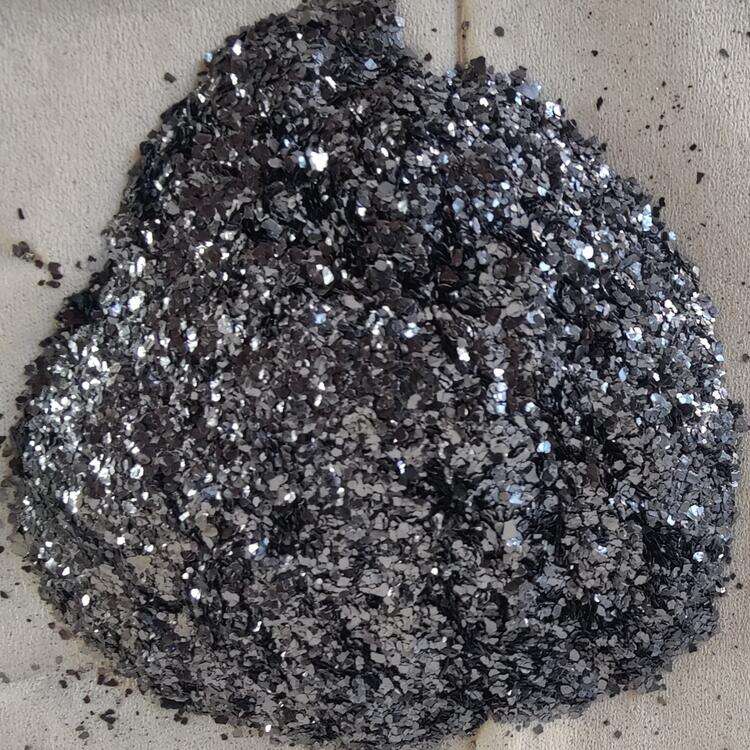

In the world of industrial materials, graphite flakes play a crucial role across numerous applications, from energy storage to lubricants and beyond. The distinction between natural and synthetic graphite flakes represents a fundamental choice that manufacturers and engineers must carefully consider for their specific needs. Each type offers unique characteristics and benefits that make them suitable for different applications, and understanding these differences is essential for making informed decisions in material selection.

The journey of graphite from its discovery to modern industrial applications showcases the remarkable versatility of this material. While natural graphite flakes have been used for centuries, synthetic variants have emerged as a technological advancement to meet specific industrial demands. This comprehensive exploration will delve into the key differences, applications, and considerations for both types of graphite flakes.

Formation and Production Methods

Natural Graphite Flake Formation

Natural graphite flakes form through the metamorphism of organic materials over millions of years. This process occurs under intense heat and pressure within the Earth's crust, resulting in the crystallization of carbon atoms into distinctive hexagonal structures. The formation environment significantly influences the final properties of natural graphite flakes, including their size, purity, and crystallinity.

Mining operations extract natural graphite flakes from deposits found worldwide, with significant sources in China, Brazil, and Madagascar. The extraction process involves careful separation and beneficiation to preserve the flake structure and maintain material quality. These naturally occurring deposits yield graphite flakes with varying grades and characteristics, making them suitable for diverse applications.

Synthetic Graphite Production

The manufacture of synthetic graphite flakes involves a controlled industrial process that transforms carbon-rich precursors into high-purity graphite. Common starting materials include petroleum coke and coal tar pitch. These materials undergo graphitization at temperatures exceeding 2,500°C, creating synthetic graphite flakes with precise specifications.

The controlled environment of synthetic production allows manufacturers to tailor specific properties such as particle size, shape, and purity levels. This level of control represents a significant advantage when consistent material properties are crucial for specific applications. However, the energy-intensive nature of synthetic graphite production contributes to higher production costs compared to natural graphite extraction.

Physical and Chemical Properties

Structural Characteristics

Natural graphite flakes typically exhibit more varied morphological features due to their geological formation process. These flakes often show greater crystallinity and larger particle sizes, with some specimens reaching several millimeters in diameter. The natural formation process results in excellent thermal and electrical conductivity, making them particularly valuable for certain applications.

Synthetic graphite flakes, while highly controlled in their production, generally display more uniform but smaller particle sizes. Their structure can be engineered to meet specific requirements, though they may not achieve the same degree of crystallinity as their natural counterparts. The controlled production environment ensures consistent quality and predictable performance characteristics.

Purity and Composition

Natural graphite flakes contain varying levels of impurities, depending on their geological source. While high-grade deposits can yield flakes with 90-97% carbon content, additional processing is often required to achieve higher purity levels. The presence of naturally occurring minerals and elements can affect their performance in certain applications.

Synthetic graphite flakes generally achieve higher purity levels, often exceeding 99.9% carbon content. This superior purity results from the controlled production process and careful selection of precursor materials. The ability to maintain consistent purity levels makes synthetic graphite flakes particularly suitable for applications requiring high-performance standards.

Industrial Applications and Performance

Energy Storage Applications

In the rapidly growing energy storage sector, both natural and synthetic graphite flakes serve as crucial materials for battery anodes. Natural graphite flakes, with their superior electrical conductivity and cost-effectiveness, remain a popular choice for many battery manufacturers. Their larger particle sizes can contribute to higher energy density in certain battery designs.

Synthetic graphite flakes often find preference in high-performance batteries where consistent quality and superior cycling stability are paramount. Despite higher production costs, their controlled properties and excellent purity levels make them ideal for advanced energy storage applications where reliability and longevity are critical factors.

Thermal Management Solutions

The thermal conductivity of graphite flakes makes them excellent candidates for heat management applications. Natural graphite flakes, particularly larger sizes, excel in thermal spreaders and heat sinks. Their cost-effective nature and good thermal performance make them attractive for various cooling solutions.

Synthetic graphite flakes offer more precise control over thermal properties, making them suitable for specialized applications requiring specific heat dissipation characteristics. Their consistent quality ensures reliable performance in critical thermal management systems, though at a higher cost point.

Economic Considerations and Market Dynamics

Cost Factors and Availability

Natural graphite flakes generally offer a more economical solution, with pricing influenced by deposit quality, processing requirements, and market demand. The availability of natural graphite depends on geological resources and mining operations, which can lead to supply chain considerations for manufacturers.

Synthetic graphite flakes command higher prices due to their energy-intensive production process and specialized manufacturing requirements. However, their production can be scaled according to demand, providing more stable supply chains. The choice between natural and synthetic often involves balancing cost considerations with performance requirements.

Market Trends and Future Outlook

The graphite flakes market continues to evolve with increasing demand from emerging technologies, particularly in the electric vehicle and energy storage sectors. Natural graphite flakes maintain strong market presence due to their cost-effectiveness and environmental considerations, as their production generally requires less energy than synthetic alternatives.

Synthetic graphite flakes are gaining market share in high-tech applications where performance specifications are critical. Ongoing research and development efforts focus on improving production efficiency and reducing costs while maintaining the advantages of synthetic graphite flakes.

Frequently Asked Questions

What are the main advantages of natural graphite flakes over synthetic ones?

Natural graphite flakes typically offer better cost-effectiveness, larger particle sizes, and excellent thermal and electrical conductivity. They also require less energy to produce, making them more environmentally friendly in terms of carbon footprint.

How do synthetic graphite flakes achieve higher purity levels?

Synthetic graphite flakes achieve higher purity through controlled production processes using carefully selected precursor materials and high-temperature treatment above 2,500°C, which eliminates most impurities and ensures consistent carbon content above 99.9%.

Which type of graphite flakes is better for battery applications?

The choice depends on specific battery requirements. Natural graphite flakes offer cost-effectiveness and good conductivity for standard applications, while synthetic graphite flakes provide superior cycling stability and consistent performance for high-end battery systems. Many manufacturers opt for a blend of both types to optimize performance and cost.