Understanding Graphite Crucibles in Metal Processing Graphite crucibles have become indispensable tools in modern metallurgy and metal processing industries. These specialized vessels, crafted from high-quality graphite material, serve as containers ...

VIEW MORE

Exploring the Versatility of Graphite in Industrial Lubrication and Sealing Graphite has long been recognized as one of the most versatile materials in industrial applications, particularly in the fields of lubrication and sealing. Its unique molecu...

VIEW MORE

Exploring the Superior Material Choice for High-Temperature Equipment In industrial thermal systems, material selection is paramount to achieving operational stability, efficiency, and durability. For furnace applications, where exposure to extreme ...

VIEW MORE

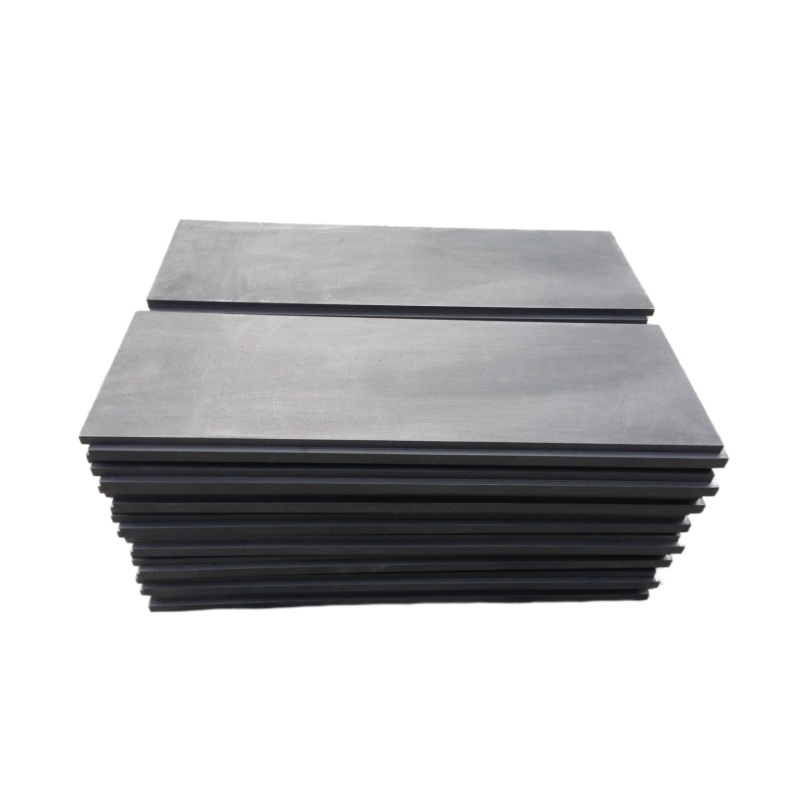

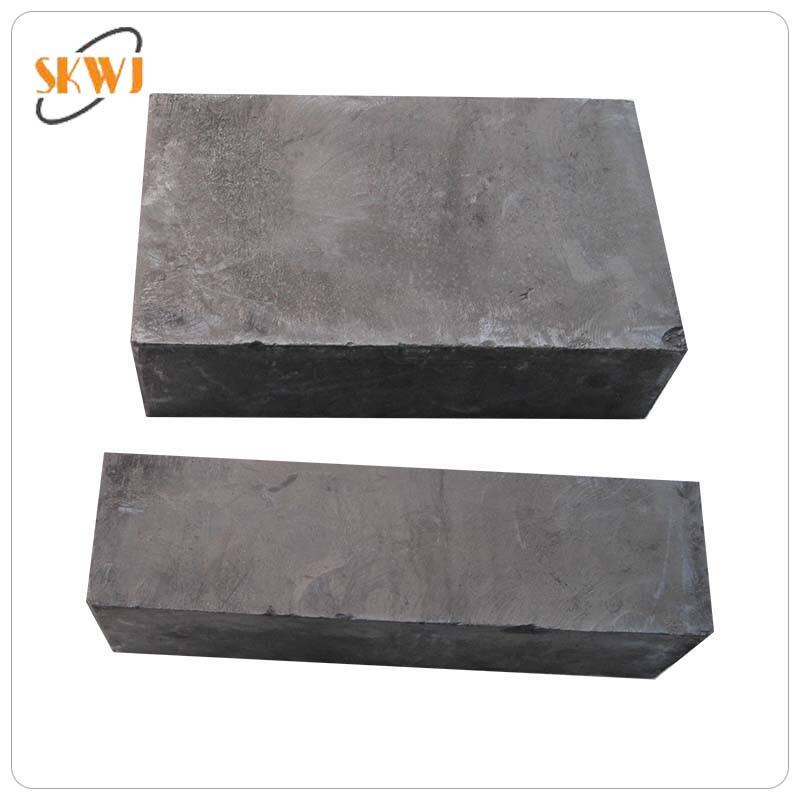

Understanding the Heat Transfer Efficiency of Carbon-Based Materials In high-temperature and precision-demanding industries, the selection of thermal management materials plays a vital role in operational efficiency. Graphite blocks, known for their...

VIEW MORE

Evaluating Material Choices for Industrial Efficiency and Cost Savings In industrial engineering, material selection has a direct influence on production efficiency, operational safety, and long-term costs. Whether for machining, thermal insulation,...

VIEW MORE

Unlocking the Industrial Potential of Graphite Blocks In modern industry, the choice of material can determine the efficiency, durability, and cost-effectiveness of a process. Among the many materials employed across different sectors, graphite stan...

VIEW MORE

Graphite in Steel Production Electric Arc Furnaces (EAF) for Sustainable Steelmaking Electric arc furnaces, or EAFs, are changing how steel gets made these days. They work by using graphite electrodes to create intense heat needed to melt scrap met...

VIEW MORE

Thermal Properties of Graphite in High-Temperature Applications Exceptional Thermal Conductivity of Graphite What makes graphite so special? Look no further than its thermal conductivity numbers. We're talking about values between 200 to 500 W/mK h...

VIEW MORE

Understanding Synthetic Graphite Properties for Enhanced Performance Key Characteristics Affecting Synthetic Graphite Performance People prefer synthetic graphite because it conducts electricity really well, handles heat efficiently, and stays stro...

VIEW MORE

Understanding Synthetic Graphite Material Properties Thermal Conductivity and Stability When it comes to conducting heat, synthetic graphite stands out with thermal conductivity numbers that can hit around 200 W/mK in laboratory tests. Because of t...

VIEW MORE

Synthetic vs Natural Graphite: Key Differences Origins and Basic Definitions Looking at where synthetic and natural graphite come from shows some pretty different stories behind each type. Synthetic graphite gets made through a process involving pe...

VIEW MORE

Graphite Mold Properties in High-Temperature Environments Thermal Stability and Heat Resistance Up to 3,000°F Graphite molds have excellent thermal stability and can be used in temperatures up to 3,000°F without effectively deforming. T...

VIEW MORE