Exploring the Superior Material Choice for High-Temperature Equipment

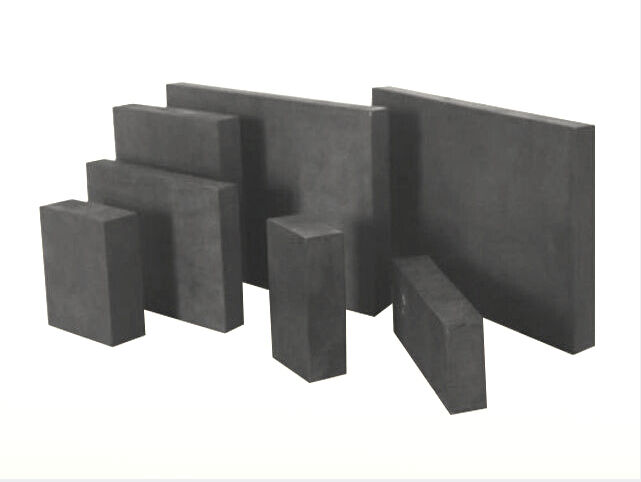

In industrial thermal systems, material selection is paramount to achieving operational stability, efficiency, and durability. For furnace applications, where exposure to extreme temperatures and chemically reactive environments is routine, graphite blocks have proven to be an outstanding material solution. Due to their unique thermal, mechanical, and chemical characteristics, graphite blocks are widely integrated into furnaces across sectors such as metallurgy, ceramics, glass manufacturing, and advanced material processing. This blog explores the many advantages of using graphite blocks in furnaces and highlights why they remain an industry-preferred material in high-heat applications.

Material Properties That Enhance Furnace Performance

Exceptional Thermal Conductivity Ensures Uniform Heat Distribution

One of the core advantages of using graphite blocks in furnaces lies in their exceptional thermal conductivity. The crystalline carbon structure of graphite allows efficient heat transfer, particularly in the plane of its layered configuration. This enables graphite blocks to conduct and spread heat quickly and evenly throughout the furnace chamber. Uniform heat distribution not only increases process reliability but also minimizes localized overheating and material fatigue. As a result, industries benefit from improved energy efficiency and reduced temperature gradients, which are critical in achieving consistent product quality in high-temperature manufacturing environments.

High Thermal Resistance and Dimensional Stability

Graphite blocks can withstand extremely high temperatures, with some grades enduring up to 3000°C in inert or reducing atmospheres. Unlike metals, which often deform, melt, or oxidize under similar conditions, graphite maintains its structural integrity. This resistance to thermal shock makes it ideal for furnace linings, heating elements, and structural supports that must endure frequent heating and cooling cycles. The low thermal expansion coefficient of graphite ensures that the blocks do not warp or crack during rapid temperature changes, which contributes significantly to the longevity and stability of the furnace structure.

Operational and Economic Advantages in Furnace Systems

Low Maintenance and Long Service Life

Furnaces constructed with graphite blocks typically require less maintenance over time compared to those using ceramic or metallic components. Graphite's non-reactive surface and high structural resilience reduce wear and corrosion, allowing it to operate for extended periods without significant degradation. This contributes to longer service life, lower downtime, and reduced replacement frequency. Maintenance savings are especially important in continuous-process industries such as steel or silicon manufacturing, where every hour of unplanned shutdown results in substantial productivity loss.

Cost Efficiency Across the Operational Lifecycle

Although the upfront cost of high-quality graphite blocks may be higher than some alternatives, the long-term savings far outweigh the initial investment. The efficiency of graphite in heat management reduces overall energy consumption, while its durability minimizes the frequency of part replacements. Additionally, graphite’s machinability allows for customized furnace parts that fit exact operational needs, reducing the need for over-engineering and material waste. These economic advantages make graphite a cost-effective solution throughout the entire lifecycle of the furnace, from initial installation to years of continuous operation.

Design Flexibility and Customization Benefits

Machinability for Complex Furnace Components

Graphite blocks are easily machined into a variety of intricate shapes, which is a major advantage in custom furnace designs. Components such as boat trays, heating rods, insulation panels, and support beams can be fabricated to tight tolerances without compromising material integrity. This is particularly beneficial in advanced manufacturing processes that require precision, such as semiconductor fabrication or sintering of specialty alloys. The ease of machining also enables rapid prototyping and efficient repair work, both of which reduce downtime and increase operational agility.

Compatibility with Advanced Furnace Configurations

Modern furnace technologies increasingly demand modularity and precision in component arrangement. Graphite blocks are highly compatible with vacuum furnaces, induction furnaces, and high-frequency heating systems due to their electrical conductivity and thermal properties. Their compatibility with various furnace designs allows engineers to tailor systems for optimized performance, regardless of scale or industry. Furthermore, graphite does not off-gas or produce harmful residues under normal operating conditions, which is crucial in cleanroom or contamination-sensitive environments.

Chemical and Environmental Resistance in Harsh Conditions

Excellent Resistance to Oxidation and Corrosion

While graphite can oxidize in open-air environments at high temperatures, it remains remarkably stable in controlled or inert atmospheres. When used in argon, nitrogen, or vacuum settings, graphite blocks exhibit strong resistance to oxidation and do not react with most industrial gases. This makes them ideal for use in furnaces handling reactive materials or corrosive gases. Additionally, various coatings and treatments can be applied to graphite to enhance its oxidation resistance when necessary. This chemical stability ensures that graphite blocks do not degrade or introduce contaminants into sensitive production processes.

Environmentally Friendly and Recyclable Material

Graphite is a naturally occurring material and can also be synthetically produced through environmentally conscious methods. The production and use of graphite blocks generate fewer emissions compared to the mining and processing of metals or certain ceramics. Furthermore, graphite components can be recycled and re-machined, contributing to circular economy practices in industrial material use. The long operational lifespan and recyclability of graphite align with global sustainability goals, particularly in industries aiming to reduce their carbon footprint without compromising performance.

Application-Specific Performance Enhancements

Crucial in High-Purity Production Environments

Graphite blocks are frequently used in applications where material purity is essential. In silicon crystal growth, semiconductor fabrication, and medical device manufacturing, contamination can lead to costly defects or failures. Because graphite does not emit volatile compounds or react with processing materials under controlled temperatures, it is an ideal furnace component for these environments. It supports clean, consistent processing conditions that meet the highest industrial standards, ensuring both product integrity and regulatory compliance.

Superior Performance in Thermal Cycling Applications

Many industrial processes involve frequent start-stop cycles, which can cause materials to expand and contract rapidly. These fluctuations often lead to stress fractures, warping, and loss of thermal efficiency in conventional materials. Graphite blocks, however, demonstrate remarkable resilience under thermal cycling conditions. Their low thermal expansion coefficient and high mechanical strength allow them to perform reliably even with frequent heating and cooling, preventing material fatigue and failure. This is a key benefit for batch-based furnace operations or processes that require frequent recalibration.

Emerging Innovations and Future Prospects

Development of Coated and Composite Graphite Materials

Ongoing research into graphite technology is producing even more durable and versatile furnace materials. Innovations include graphite blocks coated with silicon carbide, alumina, or boron nitride to enhance their oxidation resistance and surface hardness. These advanced materials combine the thermal advantages of graphite with the chemical resistance of ceramics, offering extended service life in more aggressive furnace environments. The development of composite graphite solutions is expanding the range of applications for graphite blocks, from space technology to renewable energy systems.

Increased Adoption in Sustainable Manufacturing Systems

As global industries shift toward greener production practices, graphite blocks are expected to play a larger role in sustainable furnace design. Their long service life, energy efficiency, and low maintenance needs reduce the environmental impact of thermal systems. Graphite’s compatibility with alternative energy sources, such as electric arc or solar-based heating, further supports the transition to cleaner industrial processes. With continued advancements in material science and furnace engineering, the demand for graphite blocks will likely grow across a broader range of applications in the coming years.

FAQ

How do graphite blocks improve energy efficiency in furnaces?

Graphite blocks improve energy efficiency by providing fast, uniform heat transfer with minimal energy loss. Their high thermal conductivity reduces the time and energy required to reach and maintain target temperatures, making furnaces more efficient overall.

Can graphite blocks be used in open-air furnaces?

While graphite blocks are best used in inert or vacuum environments, they can be employed in open-air furnaces if treated with protective coatings. These coatings help prevent oxidation and extend the usable life of the graphite under high-temperature air exposure.

Are graphite blocks suitable for continuous high-temperature operations?

Yes, graphite blocks are highly suitable for continuous high-temperature operations due to their excellent thermal stability, low thermal expansion, and resistance to thermal fatigue. They maintain structural integrity even at temperatures exceeding 2500°C in controlled atmospheres.

What makes graphite blocks more economical than metal or ceramic alternatives?

Despite a higher initial cost, graphite blocks offer long-term savings due to their durability, machinability, lower maintenance needs, and superior thermal performance. These factors result in lower operational costs and longer service life compared to many metal or ceramic options.

Table of Contents

- Exploring the Superior Material Choice for High-Temperature Equipment

- Material Properties That Enhance Furnace Performance

- Operational and Economic Advantages in Furnace Systems

- Design Flexibility and Customization Benefits

- Chemical and Environmental Resistance in Harsh Conditions

- Application-Specific Performance Enhancements

- Emerging Innovations and Future Prospects

- FAQ