Thermal Conduction Principles of Graphite Paper in Modern Systems

The primary function of graphite paper in thermal management systems is to facilitate the rapid movement of heat away from sensitive electronic components. Due to the unique hexagonal lattice structure of carbon atoms, this material possesses an extraordinary ability to conduct heat along its planar surface. In many high-performance devices, localized heat sources, often referred to as hot spots, can reach temperatures that threaten the stability of the entire system. By incorporating a layer of graphite paper, engineers can effectively "spread" this concentrated thermal energy across a much larger surface area. This lateral heat dissipation reduces the peak temperature at the source, allowing secondary cooling mechanisms, such as fans or heat sinks, to work more efficiently.

Anisotropic Thermal Conductivity Explained

The most defining characteristic of graphite paper is its anisotropic nature, which means its physical properties differ depending on the direction of measurement. In the horizontal plane (X-Y axis), the thermal conductivity can reach levels as high as $1500$ to $1800 \text{ W/m·K}$, which is significantly superior to traditional metals like copper or aluminum. Conversely, the thermal conductivity through the thickness of the sheet (Z-axis) is much lower, typically ranging from $5$ to $20 \text{ W/m·K}$. This directional preference is a deliberate design feature. It allows the material to act as a thermal "shield" and "spreader" simultaneously, moving heat quickly across the device's interior while preventing it from radiating directly toward heat-sensitive external casing or user-facing surfaces.

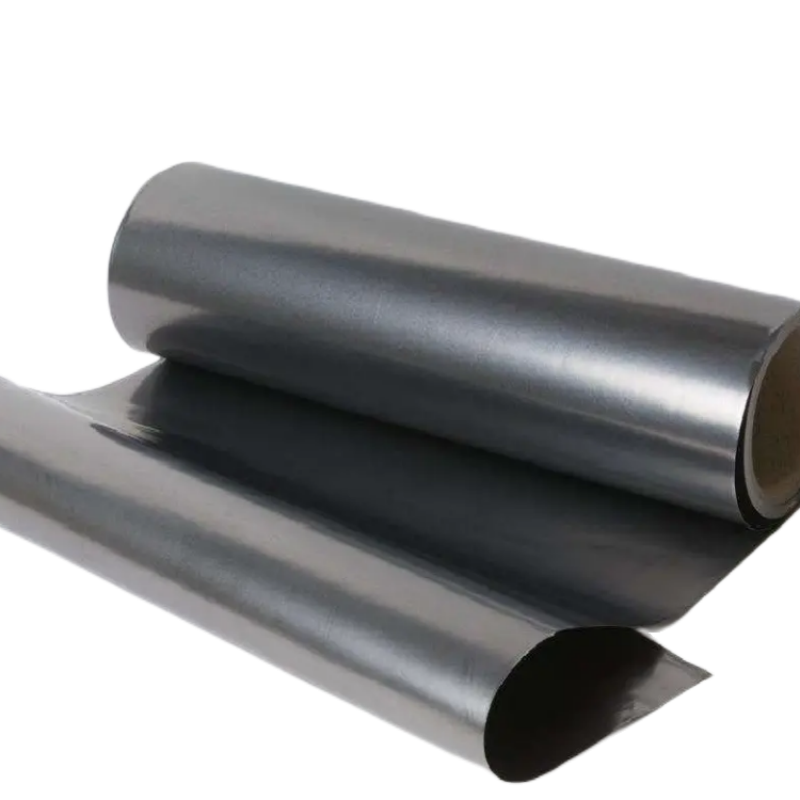

Flexibility and Conformability in Tight Spaces

Modern electronics are characterized by increasingly thin profiles and complex internal geometries, which pose a significant challenge for traditional rigid heat sinks. Graphite paper offers a highly flexible and conformable solution that can be die-cut into intricate shapes and folded over curved surfaces or corners. Because it is exceptionally thin—often ranging from $0.025 \text{ mm}$ to $0.1 \text{ mm}$—it occupies negligible volume within a chassis. This flexibility ensures that the material can maintain intimate contact with uneven component surfaces, thereby reducing thermal interface resistance. Unlike thicker thermal pads or liquid pastes that may migrate or pump out over time, a stable sheet of graphite paper provides a permanent, reliable thermal path that fits perfectly into the narrow gaps of smartphones and ultra-thin laptops.

Integration Strategies for Heat Dissipation and Shielding

Beyond its role as a simple conductor, graphite paper is often integrated into multi-layered thermal solutions to provide comprehensive environmental management. In many mobile devices, the material is used in conjunction with thin polymer films or adhesives to create a composite "thermal sticker." This allows the paper to be easily applied to the back of a display panel or a battery housing. By spreading the heat across these large-panel areas, the system utilizes the entire exterior surface of the device as a passive radiator. This method is far more effective than relying on a single exhaust point, as it leverages the principle of natural convection and infrared radiation from a larger surface area to lower internal temperatures.

Elimination of Hot Spots in Mobile Electronics

Hot spots are a major concern for user comfort and component longevity in the smartphone and tablet industry. When a processor or power management chip works at maximum capacity, it generates intense heat in a tiny area. If left unmanaged, this heat can be felt through the screen or the back cover, potentially causing the device to throttle its performance to prevent damage. Graphite paper serves as the first line of defense by immediately drawing that heat away and distributing it toward the metal frame or the device's internal shielding. This rapid redistribution ensures that no single point on the exterior surface becomes uncomfortably hot to the touch, while simultaneously allowing the internal chips to operate at higher clock speeds for longer durations.

Shielding and Isolation of Sensitive Components

In addition to thermal spreading, graphite paper can provide a degree of electromagnetic interference (EMI) shielding. Because graphite is a form of carbon that conducts electricity, a properly grounded sheet can help block or absorb unwanted radio frequency signals. This dual-functionality is highly prized in the telecommunications and aerospace sectors, where space and weight are at a premium. By using a single material to manage both heat and EMI, designers can reduce the total part count and simplify the assembly process. Furthermore, when coated with insulating layers, the paper can act as a thermal barrier, protecting delicate sensors or batteries from the heat generated by nearby power transistors or CPUs.

Reliability and Longevity in Industrial Thermal Applications

One of the most significant advantages of using graphite paper in industrial thermal management is its inherent stability over long periods. Unlike thermal greases or silicone-based pads, graphite does not "dry out," "outgas," or undergo phase separation. It is chemically inert and resistant to most acids, bases, and organic solvents. This makes it an ideal choice for equipment that must operate in harsh environments or for long-term deployments where maintenance is difficult, such as in satellite avionics or deep-sea sensors. The material’s properties actually improve or remain stable at higher temperatures, ensuring that the thermal management system remains effective even as the equipment ages.

Thermal Interface Material Replacement

Graphite paper is increasingly being used as a high-performance alternative to traditional Thermal Interface Materials (TIMs). In high-power modules, such as those found in electric vehicle (EV) inverters or 5G base stations, the interface between the heat source and the heat sink is a critical bottleneck. Standard thermal pads often have a thermal conductivity of only $1$ to $8 \text{ W/m·K}$. By replacing these with high-purity graphite paper, manufacturers can significantly reduce the thermal resistance of the junction. While the Z-axis conductivity of graphite is lower than its X-Y plane, the sheer thinness of the sheet results in a very low total thermal impedance, often outperforming much thicker traditional materials and providing a more durable solution that does not degrade under thermal cycling.

Weight Reduction and Sustainability Benefits

In the aerospace and automotive industries, every gram of weight saved contributes to fuel efficiency and overall performance. Graphite paper is remarkably lightweight compared to copper or aluminum heat spreaders, offering a density typically between $1.0$ and $2.0 \text{ g/cm}^3$. By switching from heavy metal foils to thin graphite sheets, engineers can achieve superior thermal performance with a fraction of the weight. Additionally, since high-quality graphite paper can be manufactured from natural flake graphite, it represents a more sustainable and abundant resource compared to some rare-earth-doped thermal compounds. Its durability also means fewer replacements and less waste over the lifecycle of the product, aligning with modern green manufacturing standards.

FAQ

Does graphite paper lose its effectiveness after repeated heating and cooling?

No, graphite paper is exceptionally resistant to thermal cycling and does not suffer from the degradation issues common in liquid-based or silicone-based thermal materials. Because it is a solid-state material composed of pure carbon, it does not evaporate, harden, or lose its flexibility when subjected to the expansion and contraction associated with power cycles. In fact, graphite's mechanical and thermal properties remain stable or even improve slightly as temperatures rise, making it one of the most reliable materials for long-term thermal management in both consumer and industrial applications.

Is graphite paper electrically conductive and does it pose a short-circuit risk?

Yes, graphite is an excellent electrical conductor. Because of this, it must be handled with care when integrated into electronic systems. If the edges of the graphite paper come into contact with exposed solder joints or conductive traces on a PCB, it could cause a short circuit. To mitigate this risk, thermal designers often use "encapsulated" graphite sheets, which are laminated with thin insulating films such as PET or Polyimide. These films provide the necessary electrical insulation while allowing the thermal spreading properties of the graphite to remain fully functional, ensuring the safety of the electronic assembly.

How does the performance of graphite paper compare to copper foil?

Graphite paper generally outperforms copper foil in thermal spreading applications for two main reasons. First, its in-plane thermal conductivity ($1500 \text{ W/m·K}$ or more) is nearly four times higher than that of pure copper (approximately $400 \text{ W/m·K}$). This allows for much faster heat distribution across a surface. Second, graphite paper is significantly lighter and more flexible than copper foil of the same thickness. This weight advantage is critical for mobile and aerospace applications. While copper may be better for transferring heat directly through its thickness (Z-axis), the superior spreading capability and low weight of graphite make it the preferred choice for managing surface temperatures and hot spots.

Can graphite paper be used in vacuum environments?

Yes, graphite paper is an ideal candidate for vacuum applications, such as those found in space exploration or laboratory equipment. Unlike thermal greases or many polymer-based pads, pure graphite paper does not contain volatile organic compounds (VOCs) that could "outgas" in a vacuum. Outgassing can lead to the contamination of sensitive optical surfaces or the degradation of the vacuum seal itself. Because it is a solid carbon structure, graphite paper maintains its integrity and thermal performance in a vacuum, providing a reliable thermal link between components where convection is not possible and conduction is the only available cooling path.