Razumevanje materialov za kalibre v proizvodnji

V svetu proizvodnje in obdelave kovin ima izbira med grafitna matrica in jekleno kalibrirko lahko pomemben vpliv na rezultate proizvodnje, stroške in učinkovitost. Ti dve materialni imata različne lastnosti, ki ju naredijo primerljivi za različne aplikacije, razumevanje njunih razlik pa je ključno za sprejemanje informiranih odločitev v proizvodnih procesih.

Tekoča razprava o uporabi grafitnih in jeklenih orodij še naprej oblikuje sodobne proizvodne prakse. Oba materiala ponujata edinstvene prednosti in omejitve, ki lahko proizvodnjo bodisi izboljšata bodisi ovirata, odvisno od specifičnih zahtev. Podrobneje si oglejmo ta materiala, da vam pomagamo narediti najboljšo izbiro za vaše proizvodne potrebe.

Lastnosti in značilnosti materialov

Lastnosti grafitnih orodij

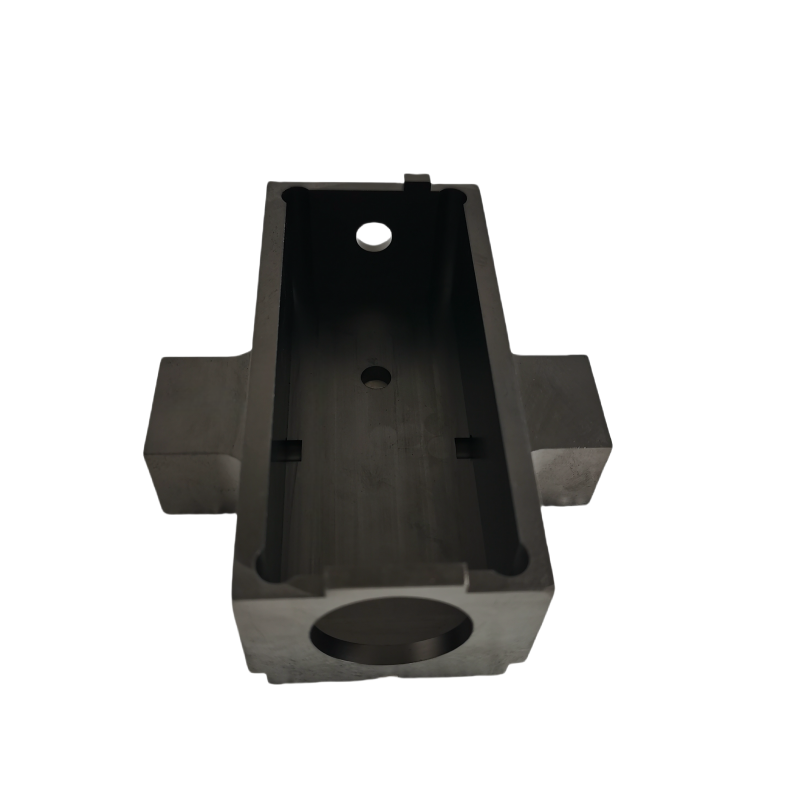

Grafitna orodja so znana po izjemnih toplotnih lastnostih in edinstveni molekularni strukturi. Material je sestavljen iz slojev ogljikovih atomov, razporejenih v heksagonalni vzorec, kar zagotavlja tako trdnost kot tudi fleksibilnost. Ta struktura omogoča grafitnim orodjem, da ohranjajo stabilnost pri visokih temperaturah, hkrati pa ponujajo odlično toplotno prevodnost.

Eden najopaznejših značilnosti grafitnih kalibrov je njihova samomaznost. Plastnata struktura omogoča, da material ohranja gladko delovanje brez dodatnega maščenja, kar zmanjšuje zahteve za vzdrževanje in izboljšuje splošno učinkovitost. Poleg tega grafitni kalibri kažejo izjemno odpornost na toplotni šok, kar jih naredi idealne za uporabo v aplikacijah z hitrimi spremembami temperature.

Značilnosti jeklenih kalibrov

Jekleni kalibri so znani po svoji odlični mehanski trdnosti in trajnosti. Kristalna struktura materiala zagotavlja odlično odpornost proti obrabi in ohranja dimenzijsko stabilnost pri visokem tlaku. Jekleni kalibri lahko prenesejo pomembne mehanske obremenitve, kar jih naredi primerne za serijo izdelave velikih količin.

Univerzalnost jekla kot materiala za orodja izhaja iz različnih razpoložljivih kakovostnih razredov in obdelav. S toplotno obdelavo in površinskim utrjevanjem lahko proizvajalci izboljšajo lastnosti materiala, da ustrezajo določenim zahtevam uporabe. Jeklena orodja ponujajo tudi odlično ponovitev in natančnost v proizvodnih procesih.

Primerjava uspešnosti

Zmogljivosti obdelave temperature

Ko gre za upravljanje temperature, grafidna orodja na splošno prekašujejo svoje jeklene kolege. Grafid ohranja strukturno celovitost pri temperaturah, ki presegajo 2000 °C, medtem ko jeklena orodja že pri veliko nižjih temperaturah izgubijo mehanske lastnosti. To naredi grafidna orodja še posebej primerna za visokotemperaturne aplikacije, kot so vroče oblikovanje in litje.

Nadpovprečna toplotna prevodnost grafita omogoča enakomernejšo porazdelitev toplote po kalupu, kar rezultira v boljši kakovosti izdelka in krajših ciklih. Jekleni kalupi, čeprav zmožni prenašati zmerno visoke temperature, morda zahtevajo dodatne hladilne sisteme, da se prepreči upogibanje ali degradacija med daljšim obratovanjem pri visokih temperaturah.

Vzdržljivost in odpornost proti obrabi

Jekleni kalupi odlično opravljajo pri aplikacijah, ki zahtevajo visoko mehansko trdnost in odpornost proti obrabi. Zmorejo ponavljane udarce in tlak brez pomembnejših deformacij, zaradi česar so idealni za dolge serije proizvodnje in aplikacije z abrazivnimi materiali. Lastna žilavost materiala omogoča ohranjanje natančnih dimenzij tudi po daljši uporabi.

Grafitne matrice, čeprav po svoji naravi trpežne, se pri uporabi pod visokim tlakom lahko prej izrabijo. Kljub temu njihove samomazalne lastnosti pomagajo podaljšati njihovo življenjsko dobo in zmanjšati zahteve za vzdrževanje v primerjavi s jeklenimi matrikami, ki jih je morda treba redno mazati in obdelovati na površini.

Stroški in gospodarski vpliv

Analiza začetnih naložb

Začetna cena jeklenih matrik običajno presega ceno grafitnih matrik zaradi bolj zapletenih proizvodnih procesov in višjih stroškov materiala. Jeklene matrice zahtevajo natančno obdelavo, toplotno obdelavo in pogosto tudi dokončno obdelavo površin, kar vse skupaj povečuje proizvodne stroške. Vendar se ti začetni stroški v določenih aplikacijah lahko izravnajo zaradi daljše življenjske dobe.

Grafitne matrice so sicer splošno manj dragocene za izdelavo, vendar lahko zahtevajo specializirano proizvodno opremo in strokovnost. Posebne lastnosti materiala zahtevajo previdno ravnanje med proizvodnjo, da se zagotovi optimalna zmogljivost in dolga življenjska doba.

Dolgoročni obratovalni stroški

Pri ocenjevanju dolgoročnih stroškov so zahteve po vzdrževanju ključne. Stalni obrati pogosto potrebujejo redno vzdrževanje, vključno z mazanjem in obdelavo površine, kar lahko poveča stroške poslovanja. Njihova večja teža vpliva tudi na stroške ravnanja in lahko zahteva močnejšo podporno opremo.

Grafitni matrici običajno povzročajo manjše stroške vzdrževanja zaradi svojih lastnih mazivnih lastnosti in lažje teže. Vendar pa jih je mogoče pri nekaterih aplikacijah pogosteje zamenjati, kar lahko poveča dolgoročne stroške glede na vzorce uporabe in zahteve proizvodnje.

Specifične zahteve glede uporabe

Idealne uporabe grafitnih žarometov

Grafitni obrati so odlični pri uporabi pri visokih temperaturah, kot so oblikovanje stekla, toplo oblikovanje kovin in keramična obdelava. Zaradi svojih odličnih toplotnih lastnosti in nizke toplotne širitve so posebej primerni za procese, ki zahtevajo natančno nadzorovanje temperature in enotno porazdelitev toplote.

Industrije, ki se ukvarjajo z jedkimi materiali, pogosto zaradi kemične inertnosti raje uporabljajo grafitne matrice. Zaradi stabilnosti materiala v agresivnih okoljih je zelo koristen pri kemični obdelavi in specializiranih proizvodnih aplikacijah, kjer se jeklo lahko hitro poslabša.

Optimalna uporaba jeklenih žarometov

Stalni obrati prevladujejo pri aplikacijah, ki zahtevajo visoko mehansko trdnost in natančnost, kot so hladno oblikovanje, stampiranje in postopki oblikovanja pod visokim pritiskom. Njihova odlična odpornost na obrabo in stabilnost dimenzij jih naredijo idealne za velike serije proizvodnje, kjer je ključnega pomena ohranjanje tesnih toleranc.

Avtomobilska in letalska industrija pogosto uporabljajo jeklene obloge zaradi njihove zanesljivosti in doslednosti pri proizvodnji kompleksnih komponent. Zaradi sposobnosti, s katero lahko material vzdrži ponavljajoče se cikle stresa in hkrati ohranja natančnost, je v teh zahtevnih sektorjih neprecenljiv.

Pogosta vprašanja

Kako dolgo trajajo grafitne matrice v primerjavi z jeklenimi matricami?

Življenjska doba grafitnih kalibrov se razlikuje glede na uporabo, v splošnem pa sega od več tisoč do desetih tisoč ciklov. Jekleni kalibri običajno trajajo dlje, pogosto dosegajo stotine tisoč ciklov pri ustrezni vzdrževalni ravni. Dejanska življenjska doba pa močno zavisi od obratovalnih pogojev, vzdrževalnih postopkov in specifičnih zahtev posamezne uporabe.

Ali lahko grafitni kalibri povsod nadomestijo jeklene kalibre?

Ne, grafitni kalibri ne morejo univerzalno nadomestiti jeklenih kalibrov. Vsak material ima svoje optimalne aplikacije, ki so odvisne od dejavnikov, kot so obratovalna temperatura, tlak in kemično okolje. Čeprav grafit odlično opravlja pri visokih temperaturah in v korozivnih okoljih, jeklo ostaja boljše za mehanske aplikacije z visokim tlakom in velikimi količinami.

Kakšne so razlike v vzdrževanju med grafitnimi in jeklenimi kalibri?

Jeklene matrice običajno zahtevajo redno mazanje, površinsko obdelavo in skrbno spremljanje obrabe. Morda potrebujejo tudi občasno ponovno poliranje, da ohranijo optimalno zmogljivost. Grafitne matrice so samomazne in zato običajno zahtevajo manj vzdrževanja, vendar jih je treba bolj previdno rokovanje, da se prepreči poškodba, ter redno pregledovati zaradi obrabe ali razpok.

Kako okoljski dejavniki vplivajo na izbiro med grafitnimi in jeklenimi matrikami?

Okoljski dejavniki vključujejo delovno temperaturo, izpostavljenost kemikalijam in stopnjo vlažnosti. Grafitne matrice delujejo bolje pri visokih temperaturah in v kemično agresivnih okoljih, medtem ko so jeklene matrice primernejše v pogojih z visokim mehanskim napetostmi in zmernimi temperaturami. Na obeh materialih lahko vpliva vlaga, vendar je jeklo bolj nagnjeno k koroziji.