Revolutionizacija litja kovin z naprednimi materiali za kalibre

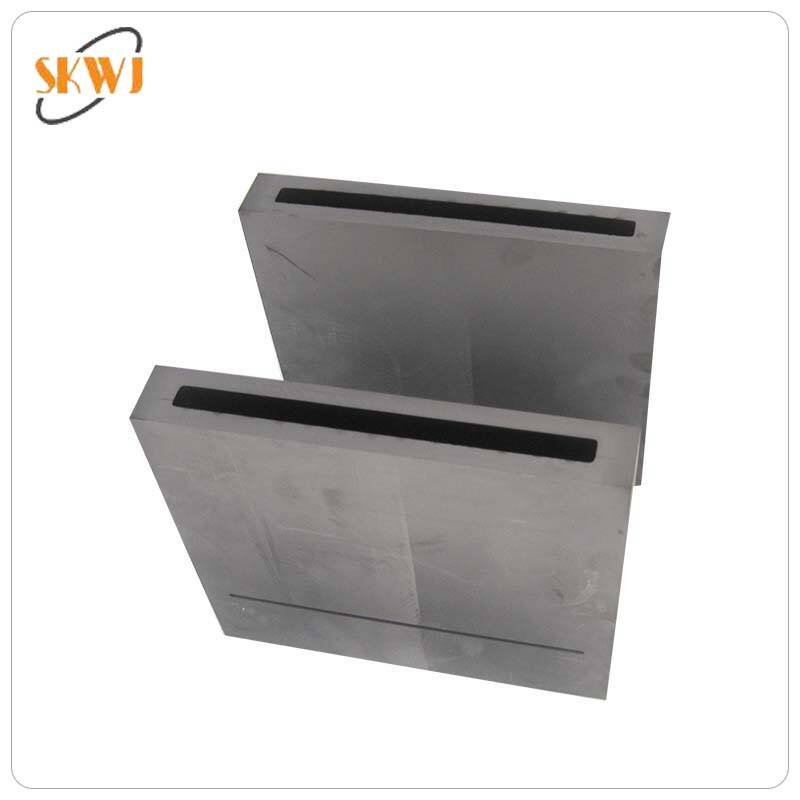

Industrija litja kovin naprej evoluira z inovativnimi tehnologijami in materiali, ki izboljšujejo učinkovitost proizvodnje in kakovost izdelkov. Med temi napredki so grafitne lijevne forme postale rešitev, ki spreminja pravila igre v postopkih litja. Te specializirane forme imajo edinstvene lastnosti, zaradi katerih postajajo vse bolj priljubljene tako v manjših livarnah kot tudi v velikih proizvodnih obratih. Njihova uporaba je spremenila način, kako proizvajalci pristopajo k procesu litja, kar je pripeljalo do pomembnih izboljšav tako pri kakovosti izdelkov kot tudi pri operativni učinkovitosti.

Lastnosti materiala in izjemno delovanje

Termalna prevodnost in upravljanje z toploto

Eden najbolj opazen vidik grafitnih kalibrov je njihova izjemna toplotna prevodnost. Ta lastnost omogoča hitro in enakomerno porazdelitev toplote po celotni litju, kar zagotavlja dosledno strjevanje raztaljenega kovine. Ko se kovina vlije v grafitne kalibre, prenos toplote poteka učinkovito, kar preprečuje nastanek vročih točk in zmanjšuje tveganje napak v končnem izdelku. Nadrejene sposobnosti upravljanja s toploto prispevajo tudi k hitrejšim ciklom hlajenja, kar na koncu poveča proizvodno zmogljivost.

Toplotna stabilnost grafitnih kalibrov ostaja konstantna tudi pri zelo visokih temperaturah, zaradi česar so ti kalibri idealni za litje materialov z visokimi točkami taljenja. Ta lastnost zagotavlja dimenzijsko stabilnost skozi več ciklusov litja, kar rezultira v natančnejših in ponovljivih rezultatih.

Trajnost in življenjska doba

Grafitne kalupi kažejo izjemno odpornost proti toplotnemu šoku in mehanskemu napetosti. Za razliko od tradicionalnih materialov za kalupe, lahko prenesejo hitre spremembe temperature brez razpokanja ali zvijanja. Ta obstojnost se prevede v daljšo življenjsko dobo in manjšo pogostost zamenjave, kar jih naredi ekonomsko učinkovito izbiro za dolgoročne litje operacije.

Lastna mazljivost materiala igra pomembno vlogo pri podaljšanju življenjske dobe kalupa. Ta samomazna lastnost zmanjšuje obrabo med postopkom litja, kar zmanjšuje potrebo po vzdrževanju in prostojih. Številni proizvajalci poročajo o znatno daljših obratovalnih obdobjih med zamenjavami kalupov po prehodu na grafitne kalupe.

Gospodarske prednosti uporabe grafitnih kalupov

Optimizacija stroškov proizvodnje

Uporaba grafitnih kalibrov pri litju pogosto vodi do znatnih varčevanj na več področjih. Začetna naložba v grafitne kalibre je lahko višja kot pri tradicionalnih alternativah, vendar se dolgoročne ekonomske koristi hitro izplačajo. Njihova daljša življenjska doba zmanjšuje pogostost zamenjave, medtem ko njihove odlične toplotne lastnosti prispevajo k nižji porabi energije med postopkom litja.

Poleg tega zaradi naravne mazljivosti grafita manjša potreba po sredstvih za razpenjanje in mazivih zmanjša stroške potrošnega materiala. Vsi ti dejavniki skupaj povzročijo nižjo skupno lastniško ceno v času obratovalnega življenja kalibra.

Povečana proizvodna učinkovitost

Uvedba grafitnih orodij znatno izboljša učinkovitost proizvodnje z hitrejšimi cikli in nižjo stopnjo odpadkov. Njihove odlične toplotne lastnosti omogočajo hitrejše cikle segrevanja in hlajenja, kar omogoča več litijev na izmeno. Enakomerna porazdelitev toplote tudi zmanjšuje napake, kar pomeni manj odpadkov in potrebe po popravilih.

Poleg tega zagotavlja dimenzijska stabilnost grafitnih orodij višjo ponovljivost pri serijah proizvodnje, kar vodi k bolj konstantni kakovosti izdelkov in manj zavrnjenih delov. Ta izboljšana učinkovitost se neposredno preliva v višjo produktivnost in boljšo izkoriščenost virov.

Izboljšave kakovosti in izboljšanje izdelkov

Odličnost površinskega zaključka

Nadrejene površinske lastnosti grafitnih kalibrov prispevajo k izjemni kakovosti površine ulitkov. Gladka površina materiala in naravna podmazanost povzročita minimalne površinske napake in izboljšano reproduciranje podrobnosti. Uliti deli običajno zahtevajo manj naknadne obdelave, kar zmanjšuje tako čas proizvodnje kot povezane stroške.

Možnost doseganja drobnih podrobnosti in gladkih površin naredi grafitne kalibre še posebej vredne v industrijah, kjer sta pomembna estetski videz in natančne dimenzije, na primer pri proizvodnji avtomobilov in potrošniških dobrin.

Tonalna natančnost in doslednost

Grafitni kalibri ohranjajo svojo dimenzijsko stabilnost tudi po večkratnih toplotnih ciklih, kar zagotavlja dosledno geometrijo delov med celotnim serijskim izdelovanjem. Ta stabilnost je ključna za ohranjanje tesnih dopuščenj in izpolnjevanje strogih standardov kakovosti. Nizek koeficient toplotnega raztezanja materiala pomaga minimizirati spremembe dimenzij delov, kar rezultira bolj zanesljivimi in natančnimi litimi izdelki.

Izboljšana točnost dimenzij prispeva tudi k boljšemu ujemanju sestavnih delov in zmanjšanju težav pri kontroli kakovosti v nadaljnjem proizvodnem procesu.

Okoljske in varnostne razmerje

Vpliv trajnostne proizvodnje

Uporaba grafitnih kalibrov je usklajena s trajnostnimi praksami proizvodnje. Njihova energetska učinkovitost in daljša življenjska doba prispevata k zmanjšanemu porabljanju virov in manjšemu okoljskemu vplivu. Minimalna potreba po dodatnih mazivih pomeni tudi manj kemičnih izdelkov na delovnem mestu ter manj odpadkov.

Poleg tega možnost recikliranja in ponovne uporabe rabljenih grafitnih kalibrov dodatno poveča njihove okoljske prednosti, kar jih čini bolj trajnostno izbiro za sodobne proizvodne operacije.

Izboljšave varnosti na delovnem mestu

Grafitne matrice ponujajo več prednosti za varnost v litju. Njihove odlične lastnosti toplotnega upravljanja zmanjšujejo tveganje nesreč, povezanih s toplotno izpostavljenostjo, medtem ko njihova stabilnost zmanjšuje možnost katastrofalne okvare matrice med obratovanjem. Zmanjšana potreba po mazivih in sredstvih za olajšanje izpusta prav tako ustvarja čistejše in varnejše delovno okolje z manj kemičnimi nevarnostmi.

Te prednosti za varnost prispevajo k izboljšanim delovnim razmeram in zmanjšanemu tveganju poklicnih nesreč, kar končno podpira boljše operativne rezultate in skladnost z regulativami.

Pogosta vprašanja

Kaj naredi grafitne matrice cenovno učinkovitejše od tradicionalnih materialov za matrice?

Grafitne matrice ponujajo nadpovprečno življenjsko dobo, zmanjšane zahteve za vzdrževanje in izboljšano energetsko učinkovitost med obratovanjem. Čeprav bi lahko prvotna naložba bila višja, ti dejavniki prispevajo k nižjim celotnim obratovalnim stroškom in boljšemu donosu naložbe s tekom časa.

Kako grafitne matrice vplivajo na kakovost izdelka pri litju v kalupe?

Grafitne matrice omogočajo odlično površinsko gladkost, dosledno dimenzijsko natančnost in izjemno podrobno reproducijo zaradi svojih toplotnih lastnosti in naravne mazljivosti. Te lastnosti rezultirajo v litjih višje kakovosti z manjšim številom napak in zmanjšanim potrebo po dodatni obdelavi.

Ali je mogoče grafitne matrice uporabiti za vse vrste liteh materialov?

Čeprav so grafitne matrice zelo univerzalne, so posebej primerni za materiale s srednjo do visoko točko taljenja. Njihova toplotna stabilnost in prevodnost ju naredita idealnima za večino pogostih litinskih zlitin, čeprav naj bi posamezne aplikacije ocenili glede na specifične zahteve litinskega materiala in procesa.

Kako vzdrževanje je potrebno za grafitne matrice?

Grafitne matrice zahtevajo minimalno vzdrževanje v primerjavi s tradicionalnimi materiali za matrice. Redna preverjanja obrabe, pravilno shranjevanje za preprečevanje poškodb in občasno čiščenje površin so navadno dovolj. Njihova naravna podmazanost zmanjša potrebo po dodatnih mazivih, kar poenostavi postopke vzdrževanja.