Understanding the Power of Graphite Dies in Modern Manufacturing

In the ever-evolving landscape of industrial manufacturing, the choice of materials and tools can make a significant difference in production efficiency and output quality. Among these crucial components, graphite dies have emerged as an indispensable tool in hot pressing applications, revolutionizing the way manufacturers approach their production processes. The unique properties and versatile nature of graphite dies have made them a preferred choice across various industries, from automotive to aerospace.

The implementation of graphite dies in hot pressing processes has transformed traditional manufacturing methods, offering unprecedented advantages in terms of temperature resistance, durability, and precision. As industries continue to demand higher quality standards and more efficient production methods, understanding the benefits of graphite dies becomes increasingly important for manufacturers looking to maintain a competitive edge.

The Scientific Foundation of Graphite Die Technology

Material Composition and Properties

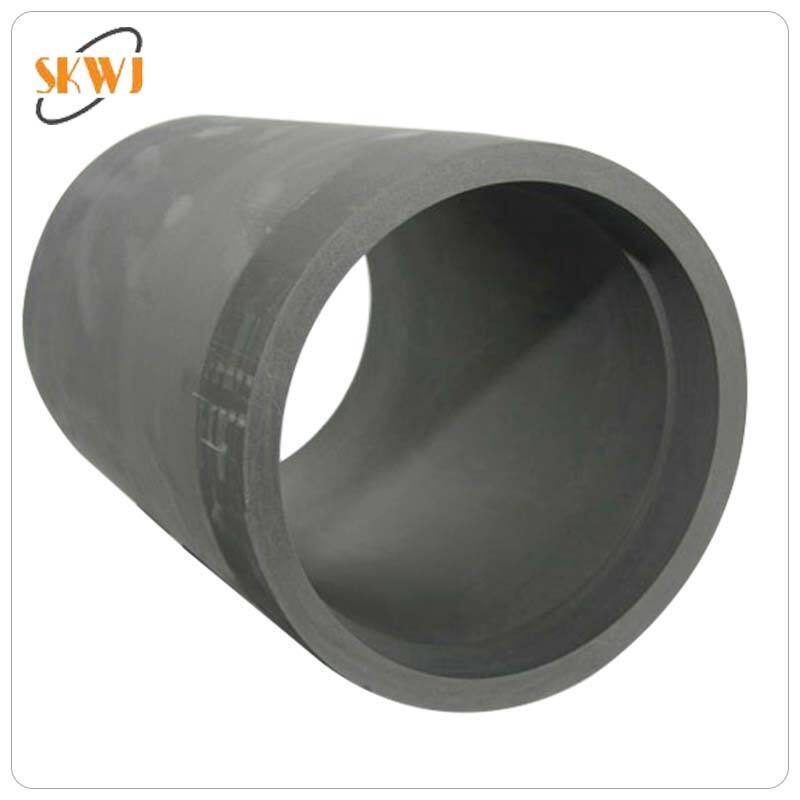

Graphite dies are engineered from high-purity graphite materials, carefully selected for their exceptional thermal and mechanical properties. The crystalline structure of graphite, with its layered carbon atoms, provides unique characteristics that make it ideal for hot pressing applications. These properties include excellent thermal conductivity, low thermal expansion, and remarkable stability at high temperatures.

The material composition of graphite dies allows them to maintain their structural integrity even under extreme conditions, making them particularly suitable for applications requiring precise dimensional control and consistent performance. The natural lubricity of graphite also reduces the need for additional lubricants during the pressing process, simplifying operations and reducing contamination risks.

Thermal Behavior and Performance

One of the most significant advantages of using a graphite die lies in its exceptional thermal behavior. The material exhibits superior thermal shock resistance, allowing for rapid temperature changes without compromising structural integrity. This characteristic enables manufacturers to implement faster heating and cooling cycles, significantly improving production efficiency.

The uniform heat distribution properties of graphite dies ensure consistent temperature throughout the pressing process, resulting in more uniform product quality and reduced risk of thermal stress-induced defects. This thermal stability is particularly crucial when working with sensitive materials or when precise dimensional control is required.

Manufacturing Applications and Benefits

Enhanced Production Efficiency

Implementing graphite dies in hot pressing operations can lead to substantial improvements in production efficiency. The material's natural properties allow for faster heating and cooling cycles, reducing overall processing times. Additionally, the exceptional durability of graphite dies means less frequent tool replacement, minimizing production downtime and maintenance costs.

The superior thermal conductivity of graphite dies enables more precise temperature control during the pressing process, resulting in better product consistency and reduced scrap rates. This improved efficiency translates directly to cost savings and higher production outputs for manufacturers.

Quality and Precision Benefits

The use of graphite dies in hot pressing applications provides unprecedented levels of dimensional accuracy and surface finish quality. The material's stability at high temperatures ensures minimal thermal distortion, allowing for tighter tolerances and more consistent results. This precision is particularly valuable in industries where component specifications must meet stringent quality standards.

The natural lubricating properties of graphite also contribute to improved surface finish quality, reducing the likelihood of material sticking or surface defects. This characteristic is especially beneficial when working with reactive materials or when producing components with complex geometries.

Cost Considerations and Economic Impact

Initial Investment Analysis

While the initial cost of graphite dies may be higher compared to some traditional alternatives, the long-term economic benefits often justify the investment. The extended service life of graphite dies, combined with reduced maintenance requirements and improved production efficiency, typically results in a favorable return on investment for manufacturers.

When evaluating the cost-effectiveness of graphite dies, it's essential to consider factors such as reduced tooling replacement frequency, decreased downtime, and improved product quality. These factors contribute to lower overall operational costs and increased production capacity.

Long-term Economic Benefits

The durability and reliability of graphite dies translate into significant long-term economic advantages. Reduced tool wear and maintenance requirements result in lower ongoing operational costs, while improved product quality leads to higher customer satisfaction and reduced warranty claims.

Furthermore, the energy efficiency associated with using graphite dies can lead to substantial savings in utility costs over time. The material's excellent thermal properties enable more efficient heating and cooling cycles, reducing energy consumption during the production process.

Environmental and Safety Considerations

Environmental Impact

Graphite dies contribute to more sustainable manufacturing practices through several mechanisms. Their extended service life reduces waste associated with tool replacement, while their energy efficiency properties help minimize the carbon footprint of manufacturing operations. Additionally, the reduced need for lubricants and other processing aids decreases the environmental impact of production processes.

The recyclability of graphite materials also adds to their environmental benefits, allowing for responsible disposal or repurposing of worn dies. This aspect aligns with increasingly important sustainability goals in modern manufacturing.

Safety Advantages

The use of graphite dies in hot pressing applications offers several safety advantages for manufacturing operations. Their excellent thermal stability reduces the risk of unexpected failures during high-temperature processing, while their natural lubricity minimizes the need for potentially hazardous lubricants and additives.

The predictable behavior and reliability of graphite dies also contribute to safer operating conditions, reducing the risk of accidents or equipment failures during production. This enhanced safety profile can lead to improved workplace conditions and reduced insurance costs.

Frequently Asked Questions

What is the typical lifespan of a graphite die in hot pressing applications?

The lifespan of a graphite die can vary significantly depending on operating conditions, but properly maintained dies typically last for thousands of pressing cycles. Factors affecting longevity include operating temperatures, pressure levels, and the materials being processed.

How does the cost of graphite dies compare to traditional alternatives?

While graphite dies may have a higher initial cost, their extended service life and reduced maintenance requirements often result in lower total cost of ownership compared to traditional die materials. The improved production efficiency and reduced downtime further enhance their cost-effectiveness.

What maintenance is required for graphite dies?

Graphite dies require minimal maintenance compared to other die materials. Regular inspection for wear or damage, proper storage to prevent contamination, and careful handling during installation and removal are the primary maintenance considerations. Their natural lubricity also reduces the need for additional maintenance procedures.