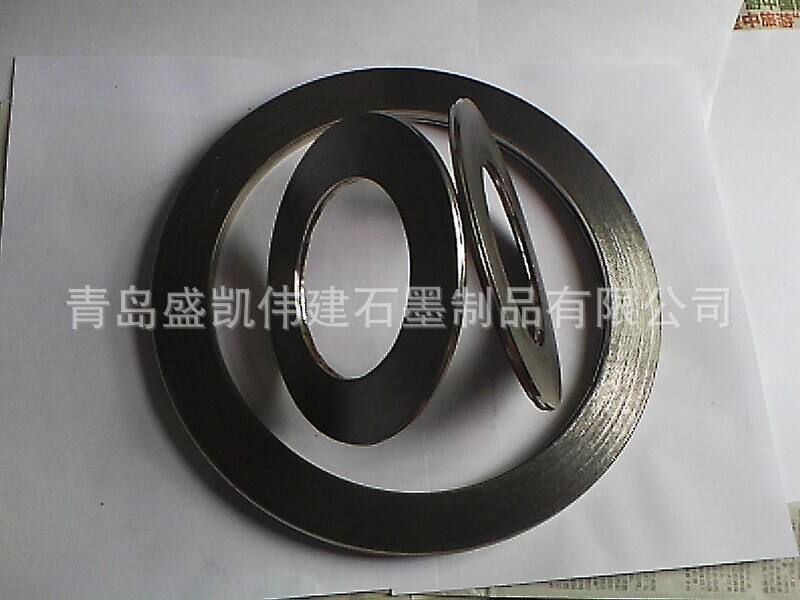

reinforced graphite gasket

Reinforced graphite gaskets represent a significant advancement in sealing technology, combining the exceptional properties of graphite with enhanced structural integrity. These gaskets are engineered by incorporating a metal insert or wire mesh within high-purity graphite foil, creating a robust sealing solution that excels in demanding industrial applications. The metal reinforcement provides mechanical strength and stability, while the graphite component ensures superior sealing performance across a wide temperature range, from cryogenic conditions to extremely high temperatures exceeding 450°C. The unique construction allows for excellent chemical resistance, making these gaskets suitable for use with various media, including acids, alkalies, and hydrocarbons. In industrial settings, reinforced graphite gaskets demonstrate remarkable resilience against thermal cycling and pressure fluctuations, maintaining their sealing integrity even under severe operating conditions. The material's inherent flexibility and compressibility enable effective sealing with lower bolt loads, while the metal reinforcement prevents over-compression and extrusion, ensuring long-term reliability and safety in critical applications.