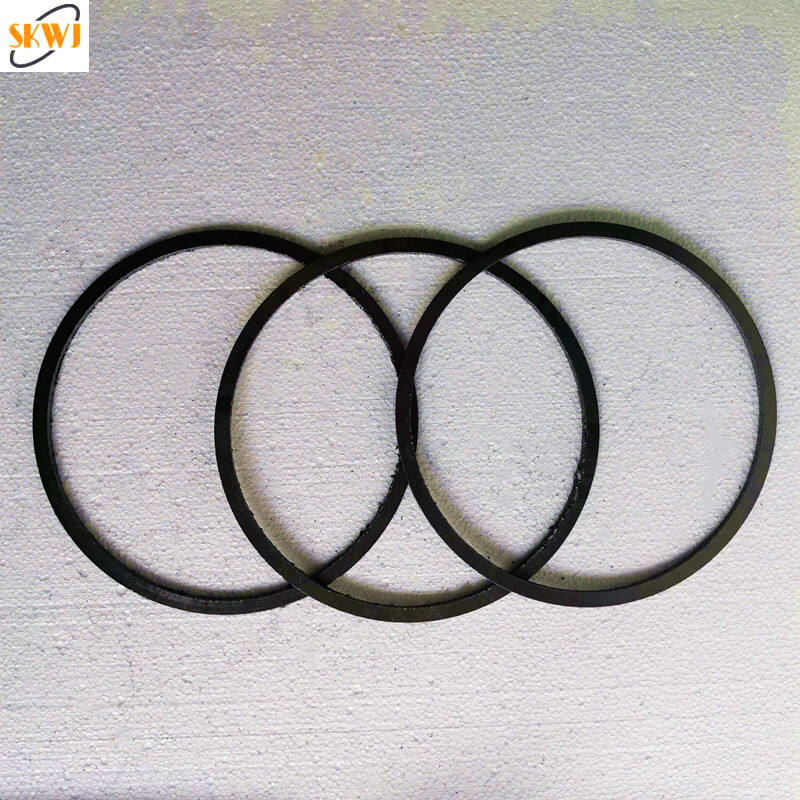

high temperature graphite gasket

High temperature graphite gaskets represent a crucial sealing solution engineered for extreme thermal environments. These specialized gaskets are manufactured using high-purity graphite material, compressed and formed into flexible sheets that maintain their integrity under intense heat conditions. The unique molecular structure of graphite allows these gaskets to perform effectively at temperatures ranging from cryogenic levels up to 850°C in oxidizing environments, and even higher in non-oxidizing conditions. The gaskets feature excellent thermal conductivity, remarkable chemical resistance, and superior compression recovery properties. They are specifically designed to prevent leakage in critical industrial applications where traditional sealing materials would fail. Their self-lubricating nature reduces friction during installation and removal, while their ability to conform to irregular flange surfaces ensures reliable sealing performance. The gaskets maintain their flexibility and do not become brittle over time, unlike many other high-temperature sealing materials. They are particularly valued in industries such as petrochemical processing, power generation, and high-temperature fluid handling systems where maintaining seal integrity is paramount to operational safety and efficiency.