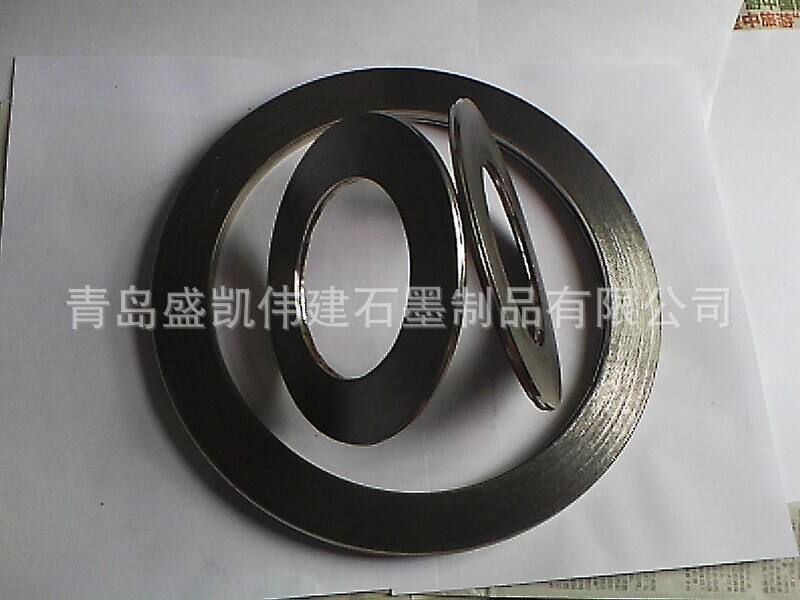

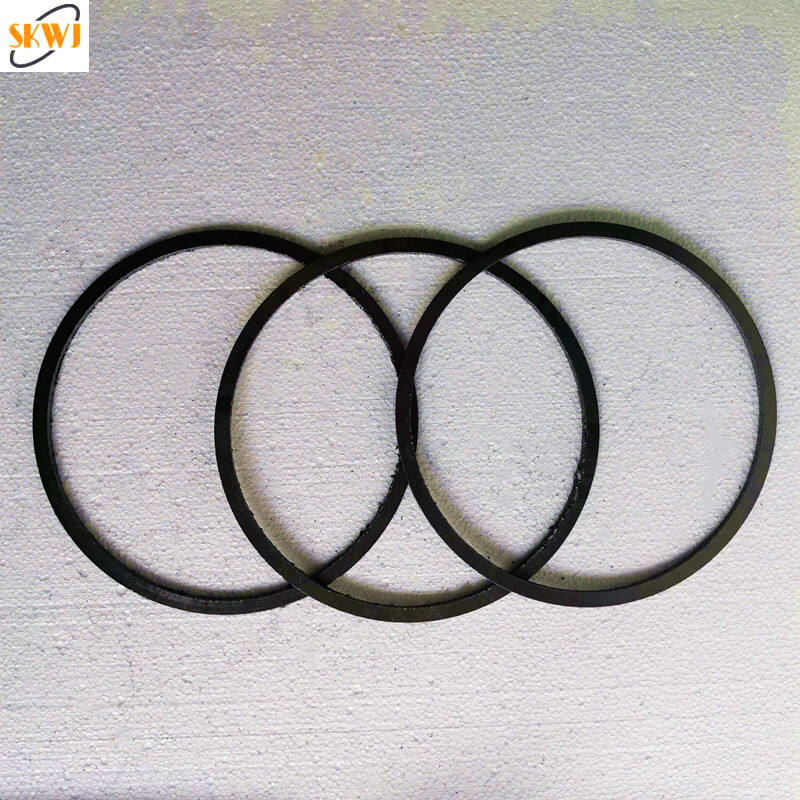

graphite laminate gasket

A graphite laminate gasket represents a sophisticated sealing solution engineered from multiple layers of flexible graphite material, specifically designed for high-performance industrial applications. This innovative sealing technology combines the natural properties of graphite with advanced manufacturing processes to create a robust and reliable gasket that excels in demanding environments. The gasket's structure consists of carefully layered graphite sheets, often reinforced with metal inserts, which provide exceptional resistance to high temperatures, ranging from cryogenic conditions to over 850°F in oxidizing environments. The unique laminated construction allows for superior compression recovery and excellent chemical resistance, making it particularly effective in applications involving steam, hydrocarbons, and aggressive chemicals. These gaskets demonstrate remarkable adaptability to flange surface irregularities, ensuring consistent sealing performance even under varying pressure conditions. In industrial settings, graphite laminate gaskets are extensively utilized in pipeline connections, heat exchangers, pressure vessels, and chemical processing equipment. Their ability to maintain seal integrity while withstanding thermal cycling and mechanical stress makes them invaluable in critical applications where leak prevention is paramount.