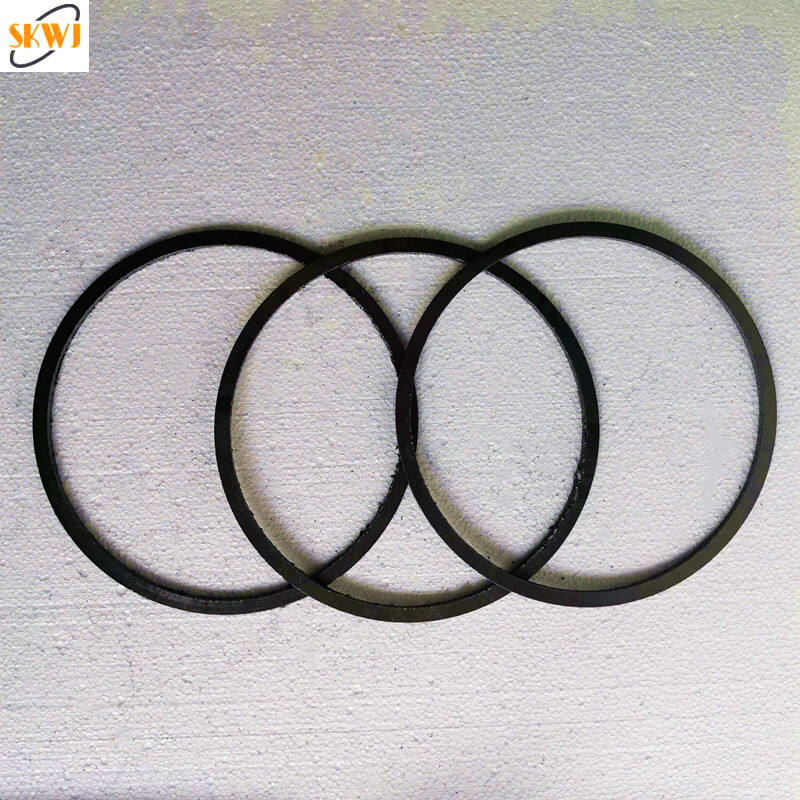

gasket graphite sheet

A gasket graphite sheet is an advanced sealing solution engineered from high-purity, expanded graphite material. This versatile component serves as a critical element in various industrial applications, providing exceptional thermal conductivity and compressibility. The sheet's unique structure consists of compressed graphite flakes that create a dense, uniform layer capable of withstanding extreme temperatures ranging from -240°C to 1000°C. Its inherent flexibility allows it to conform to irregular surfaces, ensuring reliable sealing in challenging environments. The material's chemical inertness makes it resistant to most acids, alkalies, and organic solvents, while its self-lubricating properties reduce friction and wear in dynamic applications. Gasket graphite sheets are particularly valued in industries requiring high-performance sealing solutions, such as petrochemical processing, power generation, and automotive manufacturing. The material's ability to maintain its integrity under high pressure and temperature cycling makes it an ideal choice for critical sealing applications where conventional materials might fail. Additionally, the sheets can be easily cut and formed to specific dimensions, facilitating custom solutions for various industrial needs.