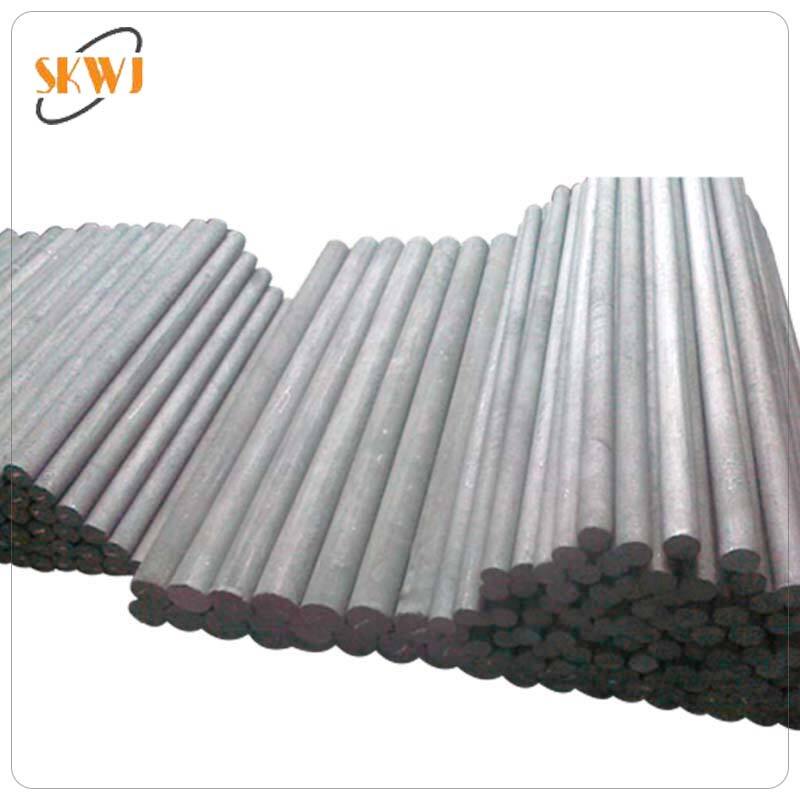

graphite plate for sale

Graphite plates represent a cutting-edge industrial solution, combining superior thermal conductivity with exceptional mechanical strength. These versatile components are manufactured through an advanced pressing and molding process, resulting in a dense, uniform structure that ensures consistent performance across various applications. The plates feature a unique molecular arrangement that facilitates excellent heat distribution and electrical conductivity, making them ideal for both high-temperature and electrochemical applications. Each plate undergoes rigorous quality control measures to maintain precise dimensional tolerances and surface finish requirements. The material composition includes high-purity graphite, processed to achieve optimal density and structural integrity. These plates demonstrate remarkable resistance to thermal shock and chemical corrosion, while maintaining their physical properties even under extreme conditions. Their applications span across multiple industries, including semiconductor manufacturing, solar cell production, chemical processing, and metallurgical operations. The plates can be customized to specific dimensions and specifications, offering flexibility for various industrial requirements. With their self-lubricating properties and low coefficient of friction, these graphite plates provide extended service life and reduced maintenance needs in mechanical applications.