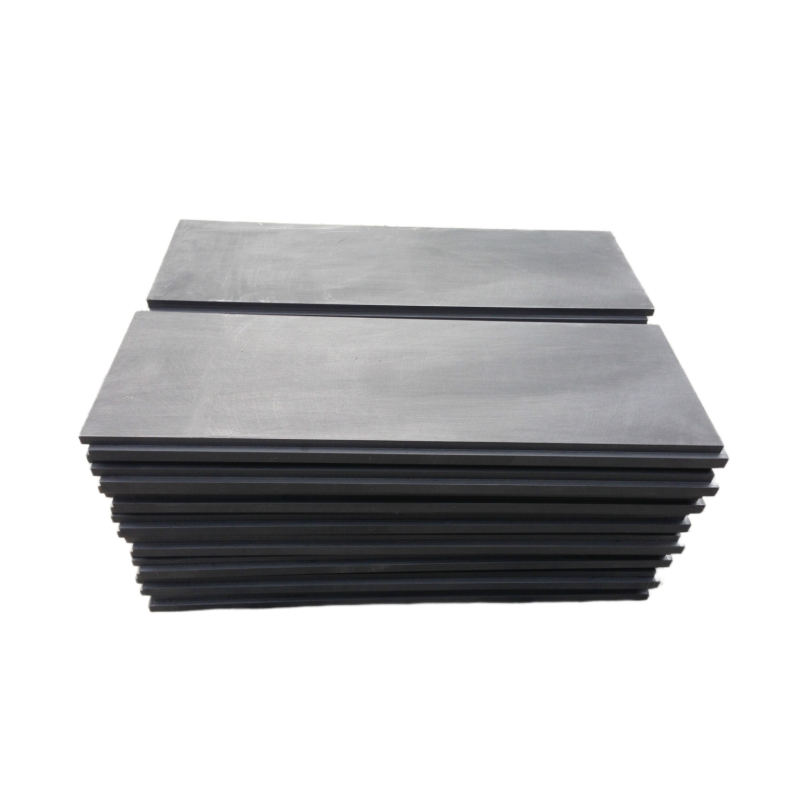

graphite plate electrode

A graphite plate electrode represents a crucial component in various electrochemical applications, combining exceptional conductivity with remarkable durability. This specialized electrode is manufactured from high-purity graphite, carefully engineered to deliver consistent performance in demanding environments. The plate structure features a uniform surface area that facilitates optimal electron transfer and ensures stable electrical conductivity throughout its operational life. These electrodes excel in applications ranging from industrial electrolysis to advanced energy storage systems, offering superior chemical resistance and thermal stability. The manufacturing process involves precise machining and quality control measures to maintain strict dimensional tolerances and surface finish requirements. Modern graphite plate electrodes incorporate advanced features such as optimized porosity and customizable surface treatments, enabling enhanced performance in specific applications. Their ability to withstand high temperatures while maintaining structural integrity makes them indispensable in electrochemical processes where reliability is paramount. The electrodes also demonstrate excellent resistance to chemical corrosion, making them suitable for aggressive environments where other materials might degrade rapidly.