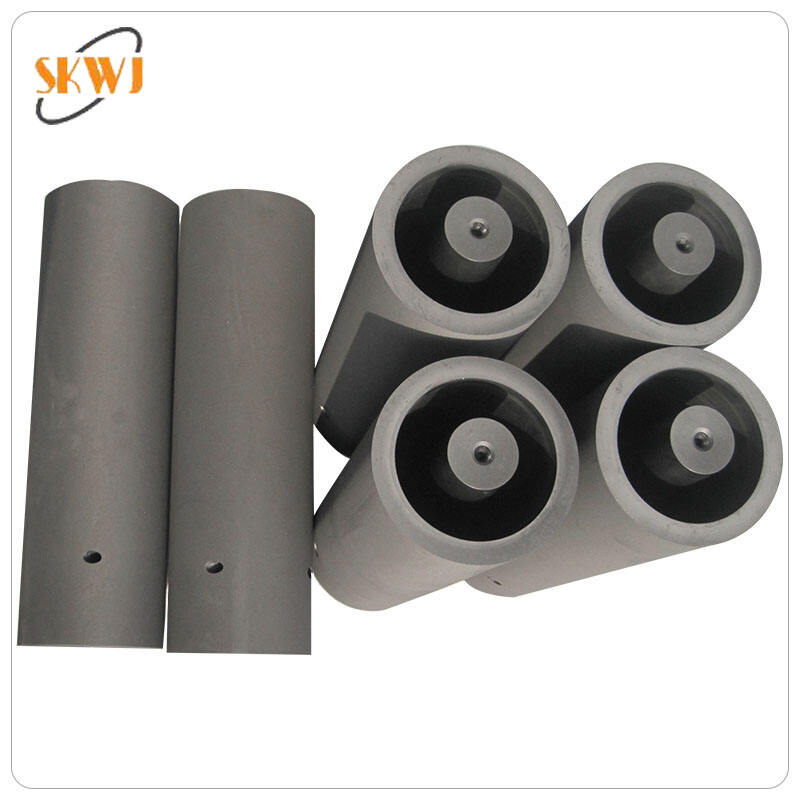

graphite heat transfer plates

Graphite heat transfer plates represent a cutting-edge solution in thermal management technology, combining exceptional thermal conductivity with remarkable durability. These specialized plates are engineered using high-purity graphite materials, precisely manufactured to facilitate optimal heat distribution and transfer in various industrial applications. The plates feature a unique molecular structure that enables rapid and efficient heat dissipation in both vertical and horizontal directions, making them ideal for complex thermal management systems. Their design incorporates precisely engineered channels and surface patterns that maximize contact area and heat exchange efficiency. These plates demonstrate superior chemical resistance and can operate effectively across a wide temperature range, from cryogenic conditions to extremely high temperatures exceeding 2000°C. The plates' lightweight yet robust construction offers significant advantages over traditional metal heat exchangers, particularly in applications requiring precise temperature control and corrosion resistance. They are widely utilized in industries such as electronics manufacturing, chemical processing, energy production, and advanced materials processing, where reliable thermal management is crucial for operational success.