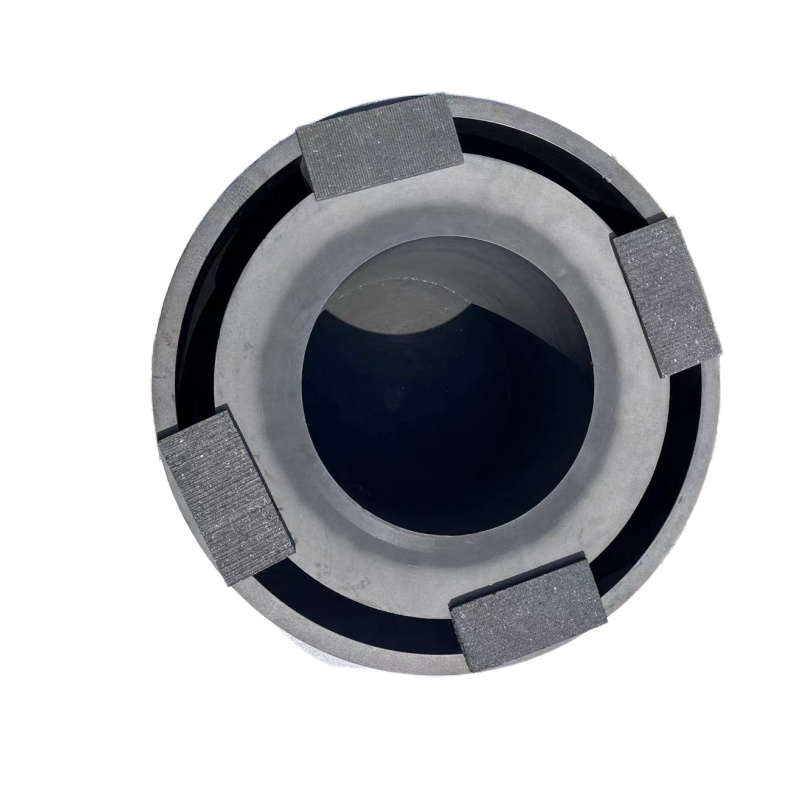

graphite packing sleeves

Graphite packing sleeves represent a crucial component in industrial sealing applications, offering superior performance in high-temperature and high-pressure environments. These specialized components are manufactured using high-purity graphite materials, carefully engineered to provide reliable sealing solutions across various industrial processes. The sleeves feature a unique construction that combines flexible graphite with reinforcing elements, creating a resilient barrier against fluid and gas leakage. Their design incorporates advanced compression technology that allows for optimal seal formation while maintaining structural integrity under extreme conditions. The sleeves demonstrate exceptional chemical resistance, making them suitable for applications involving corrosive substances and harsh chemical environments. They operate effectively across a wide temperature range, from cryogenic conditions to temperatures exceeding 850°F. The graphite packing sleeves exhibit low friction characteristics, reducing wear on equipment and extending operational life. These components are particularly valued in industries such as petrochemical processing, power generation, and chemical manufacturing, where reliable sealing is essential for safe and efficient operations.