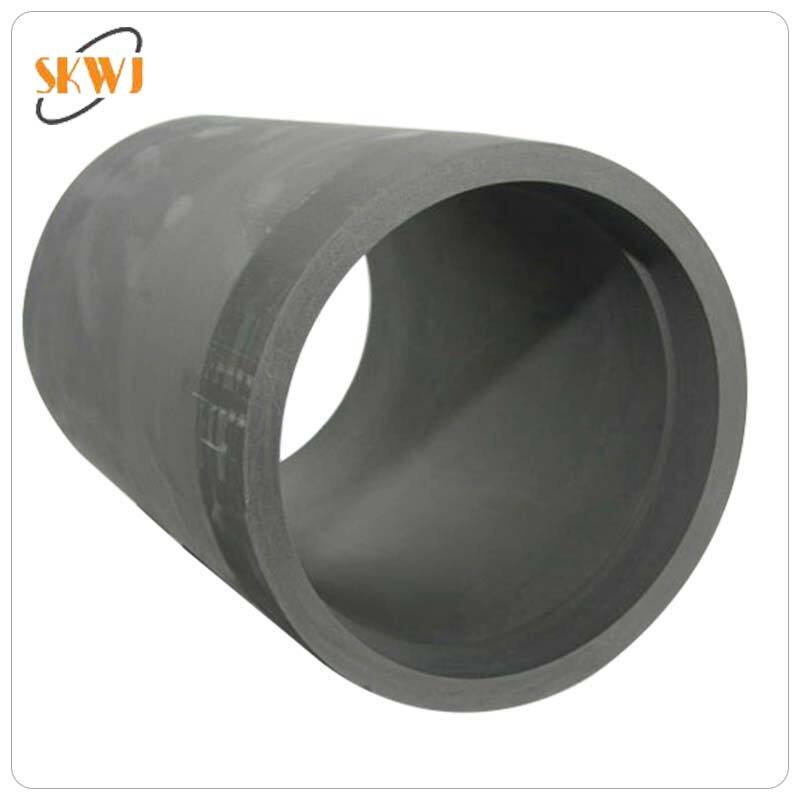

best graphite sleeve

The best graphite sleeve represents a cutting-edge solution in thermal management and protection for high-temperature applications. These precision-engineered components are manufactured from high-purity graphite materials, offering exceptional thermal conductivity and resistance to extreme temperatures up to 3000°C. The sleeve's unique construction features a seamless design that ensures uniform heat distribution and maximum protection for various industrial applications. Advanced manufacturing processes create a dense, uniform structure that maintains its integrity even under severe thermal stress. The graphite sleeve's versatility makes it ideal for semiconductor processing, metal casting, and high-temperature furnace operations. Its non-reactive nature prevents contamination in sensitive processes, while the material's natural lubricity reduces friction and wear. The sleeve's thermal shock resistance is particularly noteworthy, allowing for rapid temperature changes without compromising structural integrity. Additionally, these sleeves feature precision-machined surfaces that guarantee optimal fit and performance in various applications. The design incorporates specific dimensional tolerances that maintain stability during thermal cycling, ensuring consistent performance throughout its operational life.