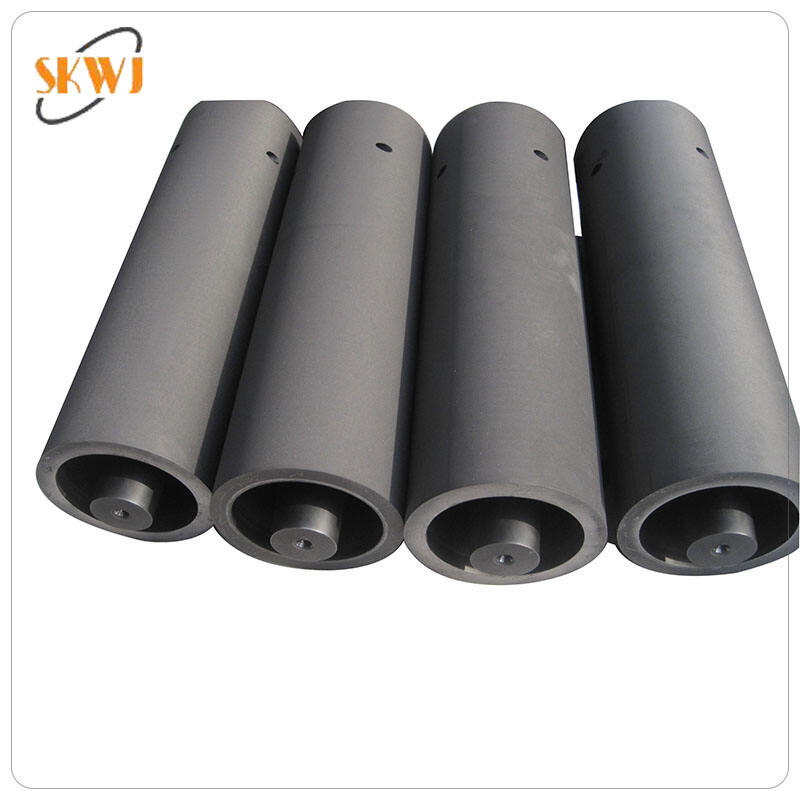

buy graphite sleeve

A graphite sleeve is an essential industrial component designed for high-temperature applications and thermal management. These precision-engineered sleeves are manufactured from high-quality graphite material, offering exceptional thermal conductivity and resistance to extreme temperatures. The sleeves feature a cylindrical design with precise dimensions, making them ideal for various industrial processes and manufacturing applications. When purchasing a graphite sleeve, customers can expect a product that combines durability with excellent thermal properties, capable of withstanding temperatures up to 2000°C while maintaining structural integrity. These sleeves are particularly valuable in metallurgy, semiconductor production, and crystal growth processes, where consistent temperature control and thermal stability are crucial. The graphite sleeve's unique composition allows for rapid heat transfer while providing protection against thermal shock and chemical corrosion. Modern manufacturing techniques ensure uniform wall thickness and surface finish, contributing to optimal performance and longevity. The sleeve's design often incorporates specific features such as precise internal diameters, customizable lengths, and specialized surface treatments to meet various industrial requirements.