Co činí grafitové formy ideálními pro vysokoteplotní aplikace

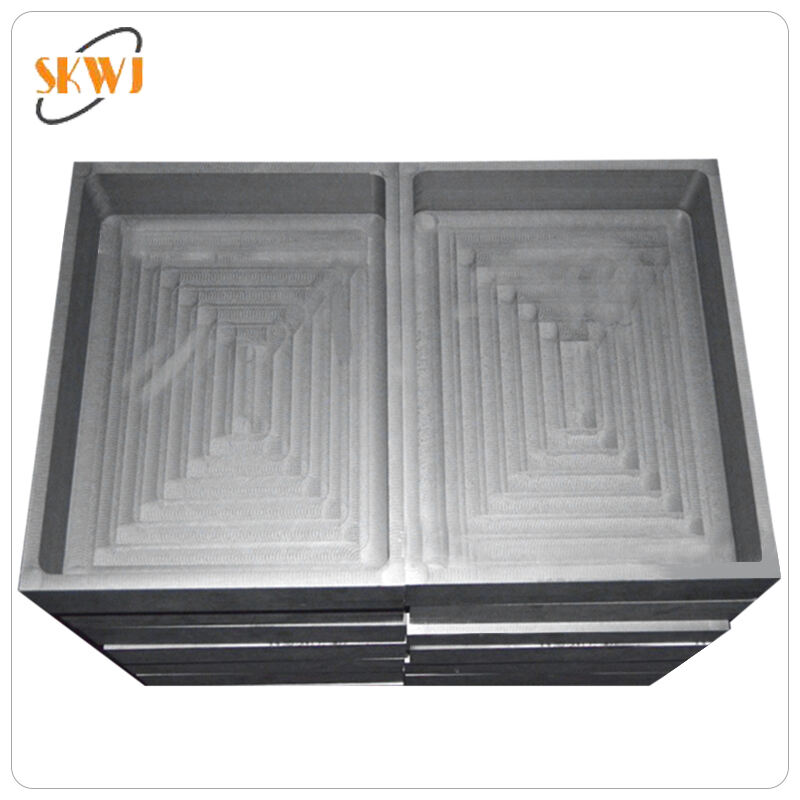

Výběr materiálu nástrojů pro tepelné zpracování určuje hranici mezi výrobním úspěchem a katastrofálním selháním. V oblasti prostředí s vysokým teplem se grafitová forma ukázala jako nepostradatelná součást v různých těžkých odvětvích. Na rozdíl od většiny materiálů, které se při stoupajících teplotách oslabují, grafit vykazuje vzácný fyzikální jev, kdy se jeho pevnost ve skutečnosti zvyšuje až do $2500^\circ C$ toto paradoxní chování z něj činí spolehlivé prostředí pro tvarování tavených kovů, skla a specializovaných keramik. Díky jedinečnému šestiúhelníkovému krystalickému uspořádání umožňuje efektivní distribuci energie, zatímco udržuje tuhé strukturní hranice. Pro inženýry a metalurgy není použití grafitové formy pouze otázkou přežití tepla; jedná se o využití předvídatelného tepelného chování uhlíkového materiálu k dosažení přesnosti, kterou jiné ohnivzdorné materiály jednoduše nemohou dosáhnout.

Základní výhoda grafitové formy spočívá v její univerzálnosti za různých atmosférických podmínek, od vakuových komor až po prostředí inertních plynů. V těchto prostředích slouží materiál jako konstrukční nádoba i tepelný regulátor. Díky vysoké emisivitě efektivně absorbuje i vyzařuje teplo, čímž zajišťuje rychlé dosažení tepelné rovnováhy obsahu. Tato schopnost je klíčová pro procesy jako slinování nebo žíhání, kde teplotní homogenita určuje konečnou krystalickou strukturu produktu. Navíc nízké náklady na opracování grafitu ve srovnání s kalenými ocelovými nástroji nebo speciálními keramikami umožňují výrobcům rychle modifikovat návrhy, což tento materiál činí stejně důležitým pro inovace jako pro sériovou výrobu.

Vynikající tepelná stabilita a vodivost

Při hodnocení výkonu jakéhokoli formy v prostředí s vysokou teplotou je tepelná vodivost hlavním ukazatelem úspěchu. Grafity formy v tomto ohledu excelují a často převyšují mnoho kovů. Tato vysoká rychlost přenosu tepla umožňuje rychlé chlazení taveniny, což je nezbytné pro dosažení jemnozrnné mikrostruktury litinových slitin. Protože se teplo tak rychle rozptýlí skrz uhlíkovou mřížku, lze proces tuhnutí kontrolovat s chirurgickou přesností. Tato rychlá tepelná odezva také snižuje dobu cyklu jednotlivých odlitků, čímž efektivně zvyšuje výstupnost slévárny nebo specializované laboratoře, aniž by byla narušena integrita nástroje.

Navíc nízký koeficient teplotní roztažnosti (CTE) grafity formy zajišťuje, že nástroj zachovává rozměrovou stabilitu i při rychlých změnách teploty. Zatímco ocelová forma se může při $800^\circ C$ , grafitová forma udržuje své původní rozměry s minimální odchylkou. Tato stabilita je životně důležitá pro přesné lití, kde se tolerance měří v mikronech. Zabraňuje vzniku „nátěku“ nebo úniku na styčných spárách forem a zajišťuje, že každá vyrobená součástka je téměř dokonalou kopií vzorového návrhu. Minimalizací vnitřních napětí způsobených tepelnou roztažností materiál také snižuje riziko praskání nebo deformace během stovek výrobních cyklů.

Chemická inertnost a nepřilnavé vlastnosti

Jednou z nejvýznamnějších překážek ve vysokoteplotní metalurgii je chemická reakce mezi taveninou a povrchem formy. Forma z grafitu poskytuje přirozeně neaktivní povrch pro širokou škálu neželezných kovů a slitin. Tato chemická inertnost zajišťuje zachování čistoty taveniny, což je obzvláště důležité při výrobě polovodičů a ingotů ušlechtilých kovů. Protože grafit se snadno netaví do slitin ani nevytváří chemické vazby s většinou kapalných kovů, je riziko kontaminace prakticky eliminováno. To umožňuje čistší proces a vyšší kvalitu konečného produktu, který splňuje přísné požadavky moderní vědy o materiálech.

Kromě své inertnosti je nepoléhavost grafitu hlavní provozní výhodou. Tavené kovy, jako je zlato, stříbro a měď, se při kontaktu s grafitovou formou chovají jako voda na voskovaném povrchu. Kapalina se svažuje do kapek, místo aby se rozlévala a přichytávala ke stěnám. To vede k samomaznému efektu, který umožňuje snadné vyjmutí ztuhlé součásti. Eliminuje tak potřebu použití drastické mechanické síly při vyjímání, čímž chrání jemné detaily odlitku a zabraňuje předčasnému opotřebení povrchu formy. Právě tato synergická kombinace chemie a fyziky umožňuje, aby nástroje z grafitu vyráběly povrchy, které téměř nevyžadují dodatečné dokončování po výrobě.

Výkon při spojitém a odstředivém lití

Aplikace grafitové formy není omezena pouze na statické tvary; je to pohonný motor pokročilých automatizovaných technik lití. U spojitého lití, kdy kov nepřetržitě přechází z kapalného stavu do tuhého profilu, forma působí jako kritické rozhraní. Kombinace vysoké odvod tepla a nízkého tření umožňuje hladký průchod kovu během tuhnutí. Bez unikátních povrchových vlastností grafitu by tření mezi pohybujícím se kovem a formou způsobilo trhání povrchu nebo vnitřní napětí, což by vedlo k vysoké míře odpadu.

Udržování konzistence při spojitém zpracování

Při spojitém lití měděných tyčí a trubek musí grafitová forma odolávat tepelnému namáhání po dobu hodin, ne-li dní. Schopnost materiálu odolávat „smáčení“ roztavenou mědí zajišťuje, že kov prochází die bez přichycení. Tento nepřetržitý tok je nezbytný pro udržení stejného průměru a kvality povrchu po několika kilometrech vyrobeného materiálu. Protože grafitem lze vyrábět s konkrétní úrovní pórovitosti, pomáhá také odvádění plynů, které by jinak mohly být v kovu zachyceny a způsobit strukturální slabiny nebo povrchové jamky.

Odolnost grafitové formy v těchto automatizovaných systémech je zvýšena díky odolnosti materiálu vůči tepelné únavě. Při spojitém lití je forma vystavena stálému tepelnému zatížení, nikoli cyklickému namáhání jako u dávkového lití. Grafity je jedinečně vhodný pro tento ustálený provoz za vysokých teplot, protože neutrpí stejné degradační procesy růstu zrn, které ovlivňují kovové formy. Dokud je prostředí udržováno bez přítomnosti kyslíku, grafity zůstává strukturně stabilní, což umožňuje dlouhé výrobní série s minimálními prostoji na výměnu formy. Tato spolehlivost se přímo promítá do nižších provozních nákladů a předvídatelnějších výrobních plánů.

Odolnost při vysokorychlostních odstředivých operacích

Odstředivé lití klade na grafitovou formu odlišné požadavky, kdy musí odolávat vysokým otáčivým silám a zároveň vyrovnávat extrémní teploty. Vysoký poměr pevnosti vzhledem k hmotnosti činí grafit ideálním materiálem pro tyto rotující formy. Když je tavená kovová hmota odstředivou silou přitlačována k vnitřním stěnám formy, grafit si zachovává tvar bez deformace nebo boubení. To zajišťuje, že výsledné válcové díly, jako jsou bušinky nebo kroužky, mají dokonale symetrickou tloušťku stěny a hustou, rovnoměrnou metalurgickou strukturu.

Rychlé chlazení způsobené grafitovou formou v odstředivém zařízení podporuje směrovou krystalizaci zvenčí dovnitř. Tento proces efektivně vytlačuje nečistoty nebo plynové bubliny směrem k vnitřnímu průměru dílu, odkud je lze později snadno odebrat broušením. Na rozdíl od ocelových forem, které se mohou při vysokorychlostní rotaci přehřát a ztratit kalení, grafity díky přirozenému tepelnému managementu udržují stabilitu procesu. Výsledkem je vysokou výtěžnost dosahující metoda výroby, která produkuje vysokovýkonné komponenty používané napříč od těžkého průmyslu až po náročné automobilové aplikace.

Role ve vakuovém slinování a práškové metalurgii

Kromě lití tekutého kovu je grafitová forma základním prvkem v práškové metalurgii a vakuovém slinování. V těchto procesech jsou kovové nebo keramické prášky stlačovány do formy a ohřívány, dokud se částice nepospojují. Často to probíhá při teplotách, které by způsobily, že tradiční nástroje z kovu roztají nebo se spojí s obrobkem. Vysoký bod tavení grafitu a jeho stabilita ve vakuu činí z něj jedinou vhodnou volbu pro výrobu vysoce hustých komponentů z taveninových kovů, jako je wolfram nebo molybden.

Přesnost v aplikacích tlakového slinování

Během horkého lisování nebo tlakového slinování se grafitová forma používá k aplikaci mechanického tlaku na prášek během jeho ohřevu. Materiál musí být dostatečně pevný, aby odolal několika tunám síly bez deformace při $2000^\circ C$ . Vysoce pevný izostatický grafit se pro tyto aplikace obvykle používá, protože zajišťuje rovnoměrné rozložení tlaku a odolává praskání za zatížení. Schopnost grafu být opracován s vysokou přesností zajišťuje, že slisovaná součást vychází s přesnými požadovanými rozměry, čímž se snižuje potřeba nákladného diamantového broušení později.

Vysoká tepelná vodivost také zajišťuje, že je prášek rovnoměrně ohříván ze všech stran. Při slinování jsou teplotní gradienty nepřítelem kvality; pokud je jedna strana součásti horkější než druhá, vede to k nerovnoměrné hustotě a možnému zkreslení. Schopnost grafu rovnoměrně rozvádět teplo svým objemem minimalizuje tato rizika. To umožňuje vyrábět velké, složité součásti, jako je pancéřování nebo specializované průmyslové řezné nástroje, s konzistentními vlastnostmi po celém dílu, což je výkon vyžadující jedinečný tepelný profil, který může poskytnout pouze uhlík.

Ochrana před kontaminací ve vakuovém prostředí

Vakuové slinování se často používá u materiálů vysoce citlivých na oxidaci nebo absorpci dusíku. Kvalitní grafitová forma má nízké odplyňování a neuvolňuje škodlivé páry do vakuové komory, které by mohly ohrozit čistotu zpracovávaného materiálu. Ve skutečnosti grafit může při některých vysokoteplotních procesech působit jako tzv. "getter", který reaguje stopovým množstvím kyslíku a dále tak čistí atmosféru kolem obrobku. Tato ochranná vlastnost je nezbytná pro výrobu pokročilých keramik a slitin kovů s vysokou čistotou, které se používají v elektronickém a leteckém průmyslu.

Interakce mezi vakuumovým prostředím a grafitovou formou také usnadňuje údržbu pecí. Jelikož nejsou potřeba žádné formovací maziva ani povlaky pro zabránění přilnavosti, vnitřek vakuumové pece zůstává čistý a bez nánosů. Tento nedostatek kontaminace prodlužuje životnost topných článků a izolace, zároveň zajišťuje, že slisované díly mají dokonalý povrchový úprav. Výběrem vhodné třídy grafitu mohou výrobci dosáhnout úrovně čistoty procesu, kterou s jinými nástrojovými materiály nelze jednoduše dosáhnout, což potvrzuje, proč zůstává grafit zlatým standardem pro vysokovakuumové tepelné procesy.

Prodloužení životnosti grafitového nářadí

I když je grafitová forma robustním a odolným nástrojem, její životnost závisí na tom, jak je spravována ve slévárně. I nejkvalitnější grafit může být poškozen, pokud je vystaven kyslíku při vysokých teplotách nebo pokud je hrubě manipulován. Porozumění mechanismům opotřebení uhlíkových materiálů je klíčem k maximalizaci návratnosti investice do těchto nástrojů. Zavedením vhodných postupů péče a skladování může výrobce zdvojnásobit či dokonce ztrojnásobit počet cyklů, které může forma vykonat, než bude vyžadovat opravu nebo výměnu.

Prevence oxidace a povrchové eroze

Oxidace je hlavní hrozbou pro grafitovou formu, když je používána při teplotách nad $400^\circ C$ za přítomnosti vzduchu. Atomy uhlíku reagují s kyslíkem za vzniku oxidu uhličitého, který postupně ničí povrch formy, čímž způsobuje bodovou korozi a ztrátu rozměrové přesnosti. Aby se tomu zabránilo, většina vysokoteplotních procesů používá ochranné atmosféry, jako je dusík nebo argon, nebo probíhá ve vakuu. Pokud musí být proces prováděn na otevřeném vzduchu, lze na povrch grafitu nanést speciální protioxidační povlaky. Tyto povlaky vytvářejí keramickou bariéru, která výrazně zpomaluje rychlost oxidace a tím dlouhodobě zachovává integritu formy.

Povrchová eroze je dalším faktorem, zejména při vysokotlakém lití nebo spojitém lití, kdy roztavený kov rychle proudí přes grafit. Ačkoli grafit je přirozeně kluzký, abrazivní povaha určitých slitin může nakonec způsobit opotřebení vnitřních rozměrů. Výběr grafitové formy s vyšší hustotou a jemnější zrnností může pomoci zmírnit tuto erozi. Hustější zrnová struktura poskytuje větší odolnost vůči mechanickému stříhání roztaveného kovu. Doporučuje se pravidelná kontrola povrchu formy, protože včasné zjištění menšího opotřebení umožňuje jednoduché leštění namísto kompletní rekonstrukce formy.

Doporučené postupy údržby a skladování

Údržba grafitová forma začíná tím, jak je chlazeno a skladováno mezi použitími. Tepelný šok pro materiál sám o sobě zřídka představuje problém, ale rychlé ochlazení může způsobit kondenzaci vlhkosti ze vzduchu v pórech grafitu. Pokud je vlhká forma náhle znovu zahřátá, pára se může rychle rozšířit a způsobit vnitřní mikrotrhliny. Aby se tomu zabránilo, měly by být formy skladovány v suchém, teplotně kontrolovaném prostředí. Pomalé předehřátí formy před prvním odlitím cyklu je rovněž osvědčenou praxí, protože zajistí bezpečné odstranění veškeré absorbované vlhkosti.

Rovněž důležitá je manipulace. I přes vysokou odolnost za tepla může být grafit křehký a náchylný k odlamování, pokud jej upustíte nebo udeříte kovovými nástroji. Použití měkkých kladiv a bezeškodných kleští při manipulaci s formou může zabránit náhodnému poškození kritických těsnicích ploch. Mnoho sléváren provozuje systematickou rotaci zásob grafitových forem, čímž každému nástroji umožní po určitém počtu použití provést čištění a kontrolu. Tento preventivní postup zajišťuje, že jakékoli povrchové vady budou odstraněny dříve, než by mohly ovlivnit kvalitu hotového výrobku, a tím udržuje vysokou úroveň přesnosti po celou dobu výroby.

Často kladené otázky

Proč se grafitová forma nevaří při teplotách, které taví ocel?

Grafit nemá tradiční teplotu tání za standardního atmosférického tlaku; místo toho sublimuje, tedy přechází přímo ze stavu pevného do plynného při přibližně $3600^\circ C$ . To je mnohem vyšší než teplota tavení oceli, mědi nebo dokonce mnoha taveninových slitin. Vzhledem k této extrémní tepelné hranici zůstává grafitová forma strukturně pevná a funkční v prostředích, kde by se většina kovových nástrojů již roztavila nebo výrazně změkla.

Kolikrát lze grafitovou formu znovu použít?

Počet opakovaného použití grafitové formy závisí velmi silně na provozním prostředí a materiálu, který se odlévá. Ve vakuu nebo inertní atmosféře může forma vydržet stovky nebo dokonce tisíce cyklů, protože k ní nedochází oxidační opotřebení. V prostředí otevřeného vzduchu při vysokých teplotách může forma vydržet pouze 20 až 50 cyklů, než se povrchová oxidace stane významnou. Použití vysokohustotního grafitu a ochranných povlaků může tento výkon výrazně prodloužit.

Je obtížné obrábět grafitovou formu do složitých tvarů?

Ve skutečnosti jednou z největších výhod grafitu je jeho vynikající obrobitelnost. Lze jej snadno soustružit, frézovat a vrtat pomocí běžného CNC vybavení. Jelikož se jedná o měkký materiál (ve srovnání s kovy), nevyžaduje drahou nástrojovou techniku pro obrábění a nevznikají při něm stejné vnitřní napětí jako při obrábění oceli. To umožňuje vytvářet velmi složité detaily a komplexní geometrie v grafitové formě, které jsou následně dokonale přeneseny na finální odlitek.

Ovlivňuje třída grafitu kvalitu odlité součásti?

Ano, jakost grafitu je rozhodující pro kvalitu konečného výrobku. Hustý jemněrýnový grafit (například izostatický grafit) zajišťuje hladší povrchovou úpravu a lepší rozměrovou stabilitu. Pokud je použit nižší jakostní, pórovitý grafit, roztavený kov se může dostat do pórů, což vede k drsnému povrchu a ztěžuje vyjímání dílu. Pro přesné aplikace výběr vysokopurého, vysokohustotního typu zaručuje nejlepší metalurgické výsledky a nejdelší životnost formy.