tube of graphite

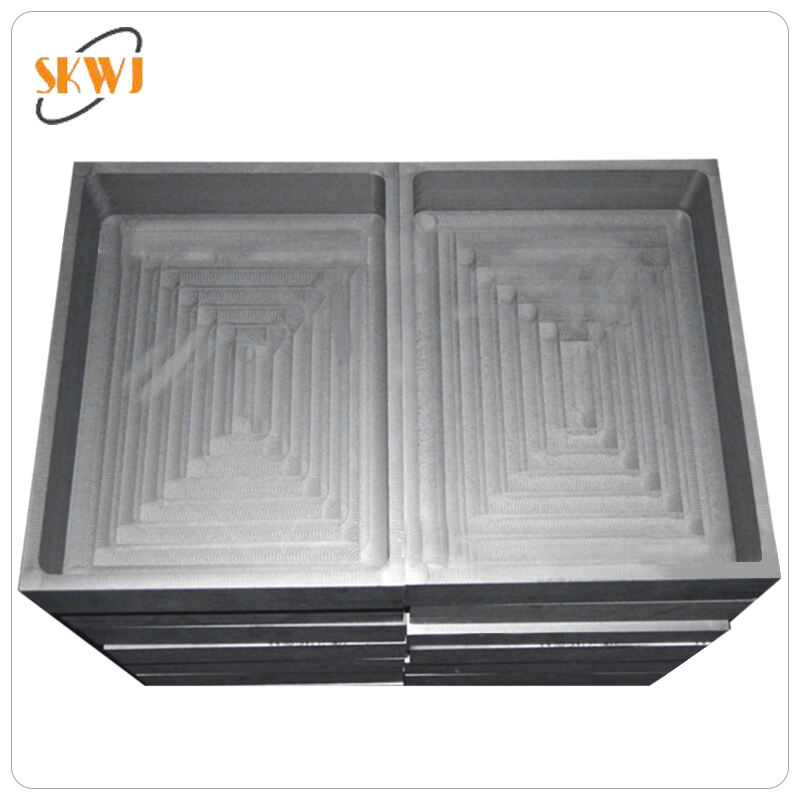

A tube of graphite represents a sophisticated industrial component that combines structural integrity with exceptional thermal and electrical properties. This cylindrical form of crystalline carbon serves as a crucial element in various industrial applications, ranging from metallurgy to nuclear engineering. The tube structure features a unique arrangement of carbon atoms in hexagonal layers, providing superior strength while maintaining relatively low weight characteristics. These tubes are engineered to precise specifications, typically ranging from several millimeters to several inches in diameter, with wall thicknesses carefully calculated to meet specific application requirements. The material exhibits remarkable resistance to high temperatures, making it ideal for furnace components and heating elements. Its self-lubricating properties significantly reduce friction in mechanical applications, while its excellent thermal conductivity ensures efficient heat transfer in thermal management systems. The tube of graphite also demonstrates impressive chemical resistance, particularly in non-oxidizing environments, making it valuable in chemical processing and semiconductor manufacturing. Modern manufacturing techniques allow for the production of these tubes with varying degrees of porosity and density, enabling customization for specific industrial needs. The material's ability to withstand thermal shock and maintain structural integrity under extreme conditions has made it indispensable in aerospace and defense applications.