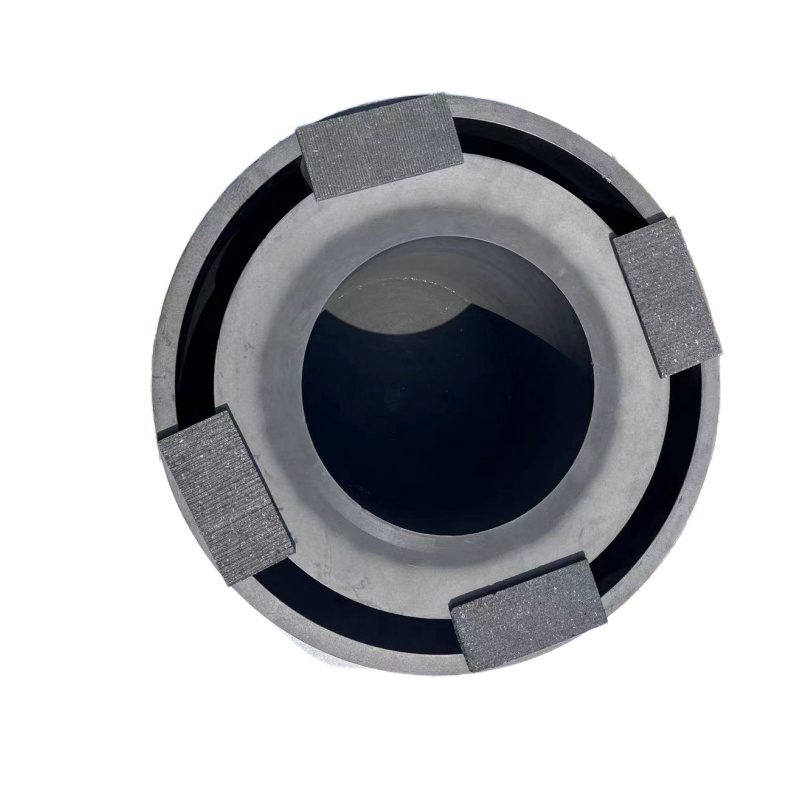

graphite pipe

Graphite pipes represent a significant advancement in industrial piping systems, offering exceptional thermal and chemical resistance properties that make them invaluable across various applications. These pipes are manufactured through a sophisticated process that involves high-temperature treatment of carbon materials, resulting in a crystalline structure that exhibits remarkable strength and durability. The pipes feature excellent thermal conductivity, making them ideal for heat exchange applications, while their inherent resistance to corrosion and chemical attack ensures longevity in aggressive environments. They can withstand temperatures exceeding 3000°C in non-oxidizing atmospheres and maintain structural integrity under extreme conditions. Graphite pipes are particularly valued in chemical processing, metallurgy, and semiconductor manufacturing industries, where their unique properties enable safe and efficient transfer of corrosive materials and high-temperature fluids. Their non-porous nature prevents material contamination, while their lightweight construction facilitates easier installation and maintenance compared to traditional metal pipes. The versatility of graphite pipes extends to their ability to handle both acidic and alkaline substances, making them an essential component in modern industrial processes where material purity and process reliability are paramount.