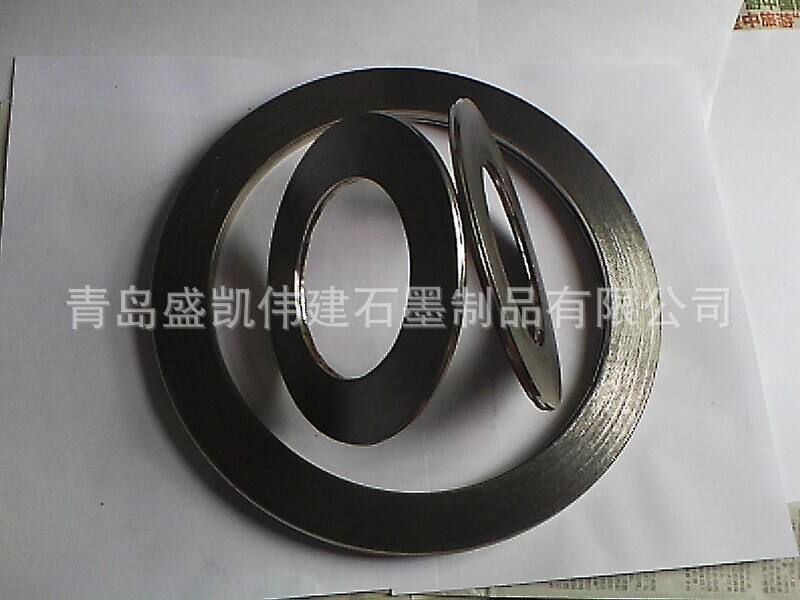

spiral wound graphite gasket

A spiral wound graphite gasket represents a sophisticated sealing solution engineered for demanding industrial applications. This high-performance gasket consists of a V-shaped metallic strip, typically stainless steel, wound in a spiral pattern with graphite filler material. The unique construction creates a resilient and robust seal capable of withstanding extreme temperatures ranging from cryogenic conditions to over 850°F. The gasket's design incorporates alternating layers of metal and graphite, providing exceptional compression recovery and maintaining seal integrity under varying pressure conditions. When compressed between flanges, the graphite filler material flows into surface imperfections while the metal spiral maintains structural stability. These gaskets excel in applications involving steam, chemicals, hydrocarbons, and other challenging media. Their versatility makes them ideal for heat exchangers, pipe flanges, pressure vessels, and various process equipment. The graphite material offers superior chemical resistance and thermal conductivity, while the metallic winding ensures mechanical strength and prevents gasket blow-out. The gasket's construction allows for excellent recovery properties, maintaining an effective seal even during thermal cycling and pressure fluctuations.