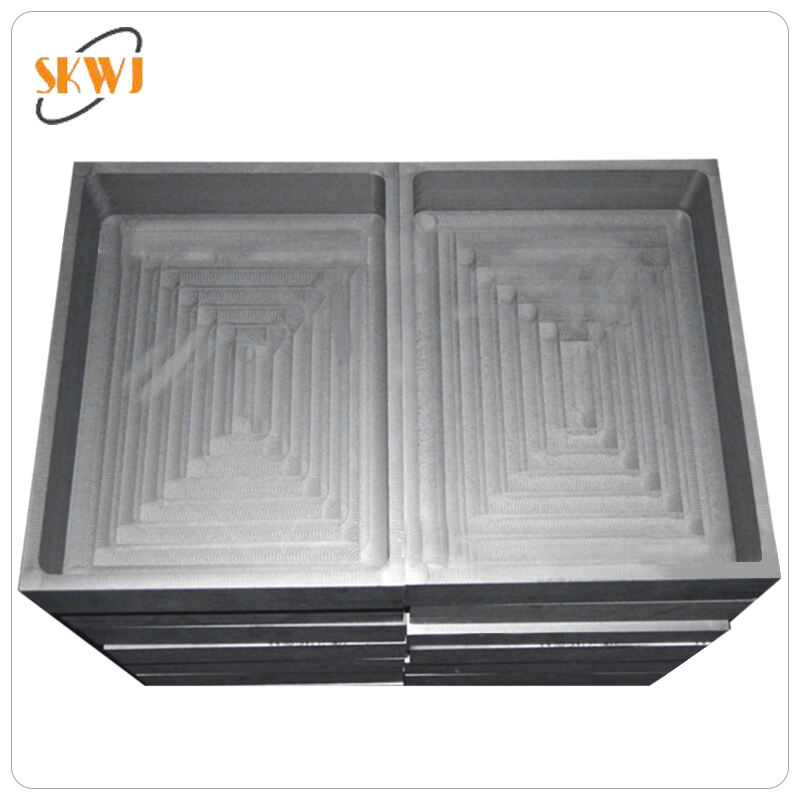

melting graphite crucible

A melting graphite crucible represents a critical tool in metallurgical and industrial processes, engineered specifically for high-temperature metal melting operations. These specialized vessels are constructed from high-quality graphite materials, carefully designed to withstand extreme temperatures while maintaining structural integrity. The crucible's composition features a dense graphite matrix that offers exceptional thermal conductivity and resistance to thermal shock, making it ideal for melting various metals and alloys. The unique properties of graphite allow these crucibles to maintain consistent heating patterns, essential for achieving uniform melting results. They are particularly valued in foundry operations, precious metal processing, and laboratory applications where precise temperature control is crucial. The crucible's design typically incorporates features such as reinforced walls and optimized wall thickness to enhance durability and heat distribution. Modern melting graphite crucibles often include advanced surface treatments that extend their operational lifespan and improve their resistance to oxidation at high temperatures. These vessels come in various sizes and configurations to accommodate different melting requirements, from small-scale jewelry making to industrial-scale metal processing operations.