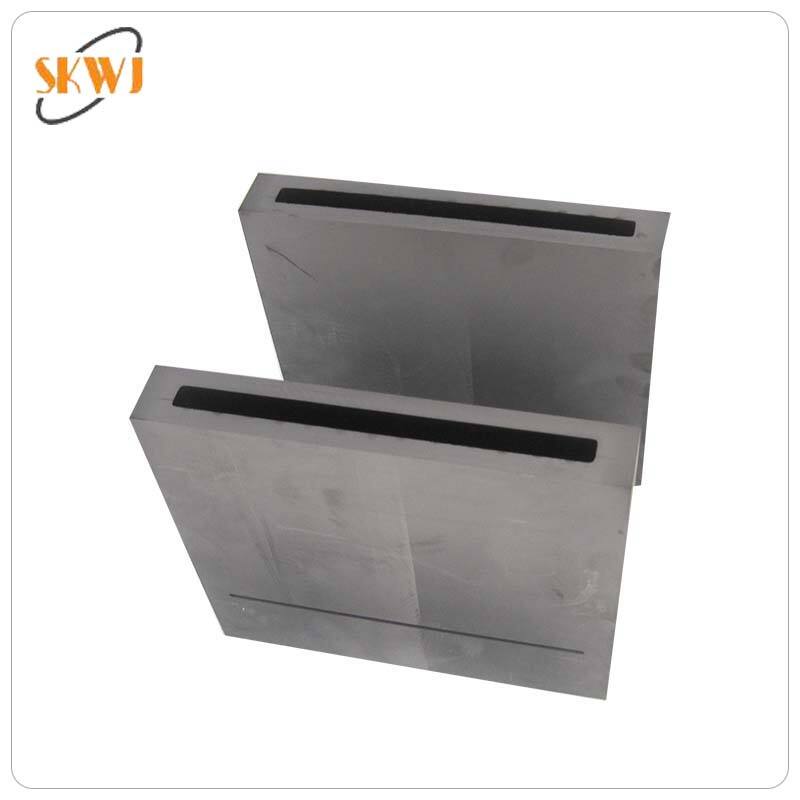

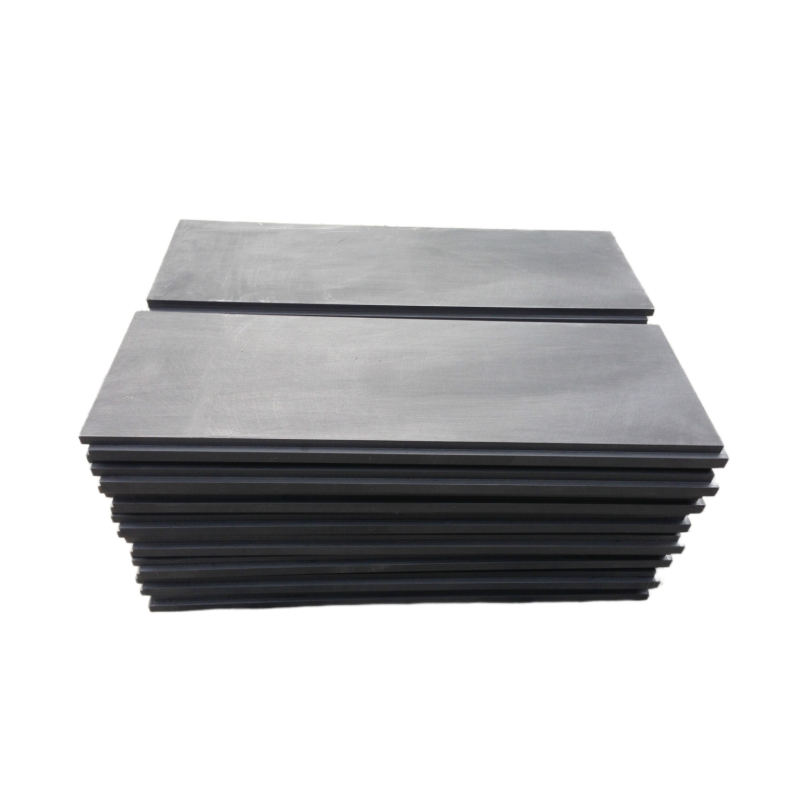

high purity graphite crucible

High purity graphite crucibles represent a pinnacle of materials science engineering, specifically designed for high-temperature applications in metal processing and semiconductor industries. These specialized vessels are manufactured using premium-grade graphite with purity levels exceeding 99.99%, ensuring minimal contamination during melting operations. The crucibles feature exceptional thermal conductivity, allowing for uniform heat distribution and precise temperature control during melting processes. Their unique molecular structure provides outstanding resistance to thermal shock, enabling rapid heating and cooling cycles without compromising structural integrity. The high purity composition significantly reduces the risk of metal contamination, making these crucibles ideal for precious metal casting and semiconductor crystal growth. These vessels maintain their strength and stability at temperatures exceeding 2000°C, while their chemical inertness prevents unwanted reactions with molten materials. The advanced manufacturing process includes specialized treatment to enhance density and reduce porosity, resulting in extended service life and improved performance in demanding industrial applications. Modern high purity graphite crucibles also feature optimized wall thickness and geometric designs that maximize energy efficiency while ensuring safe handling and operation.