graphite crucible price

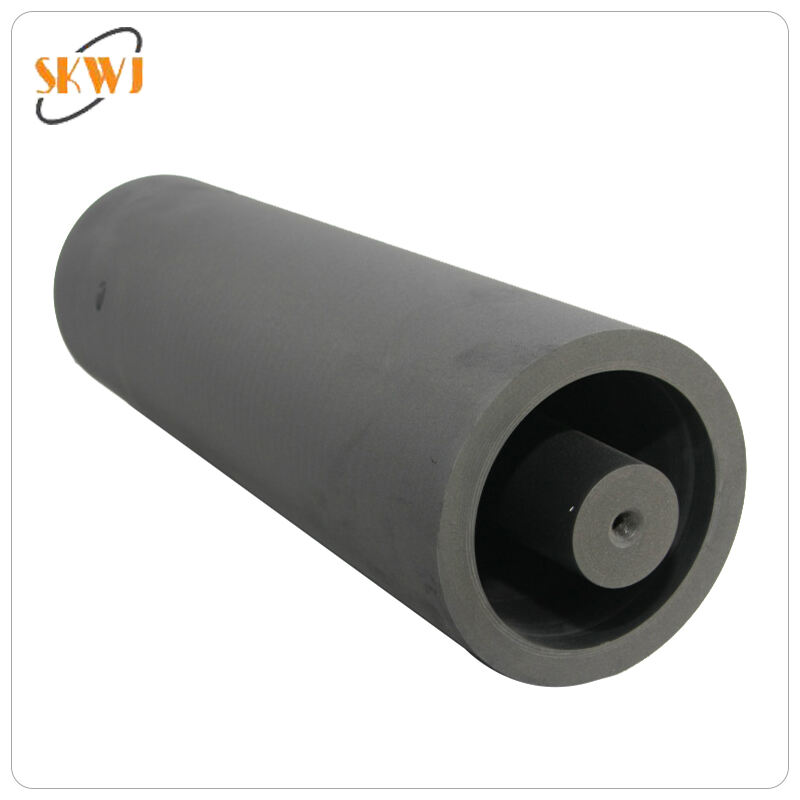

Graphite crucible pricing represents a critical consideration in various industrial applications, particularly in metallurgy and foundry operations. These essential vessels, crafted from high-quality graphite materials, demonstrate exceptional thermal conductivity and resistance to high temperatures, making them invaluable for melting and casting operations. The price of graphite crucibles varies significantly based on factors such as size, purity grade, and manufacturing quality. Modern graphite crucibles feature advanced thermal shock resistance and extended service life, offering cost-effective solutions for metal processing industries. The price structure typically reflects the crucible's capacity, ranging from small laboratory sizes to large industrial units, and considers the graphite's density and purity levels. These crucibles excel in maintaining consistent temperatures during melting processes, reducing energy consumption and operational costs. Additionally, their non-reactive nature with most metals and alloys justifies their price point, as they prevent contamination and ensure high-quality output in metallurgical processes.