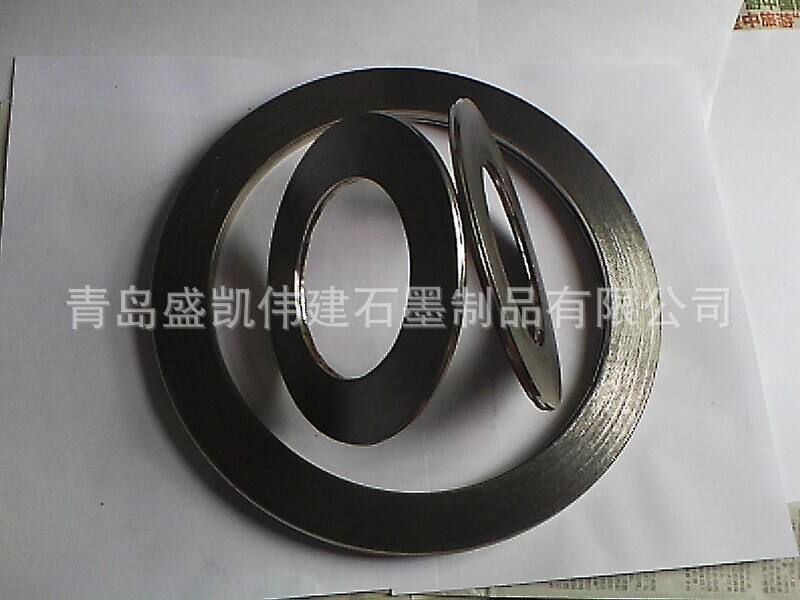

graphite filler spiral wound gasket

The graphite filler spiral wound gasket represents a sophisticated sealing solution designed for high-pressure and high-temperature applications in industrial settings. This innovative gasket consists of a V-shaped metallic strip spirally wound with graphite filler material, creating alternating layers that provide exceptional sealing performance. The metallic strip, typically made from stainless steel or other corrosion-resistant alloys, offers structural integrity while the graphite filler ensures superior sealing properties. The unique design incorporates inner and outer rings that guide installation and prevent over-compression, ensuring optimal performance under varying conditions. These gaskets excel in maintaining seal integrity across a wide temperature range, from cryogenic conditions to extremely high temperatures up to 450°C. The graphite filler material's natural lubricity and chemical resistance make it particularly suitable for applications involving aggressive media, while its ability to conform to flange surface irregularities ensures reliable sealing even under fluctuating pressure conditions. The gasket's construction allows for excellent recovery properties and resistance to relaxation, contributing to extended service life and reduced maintenance requirements.