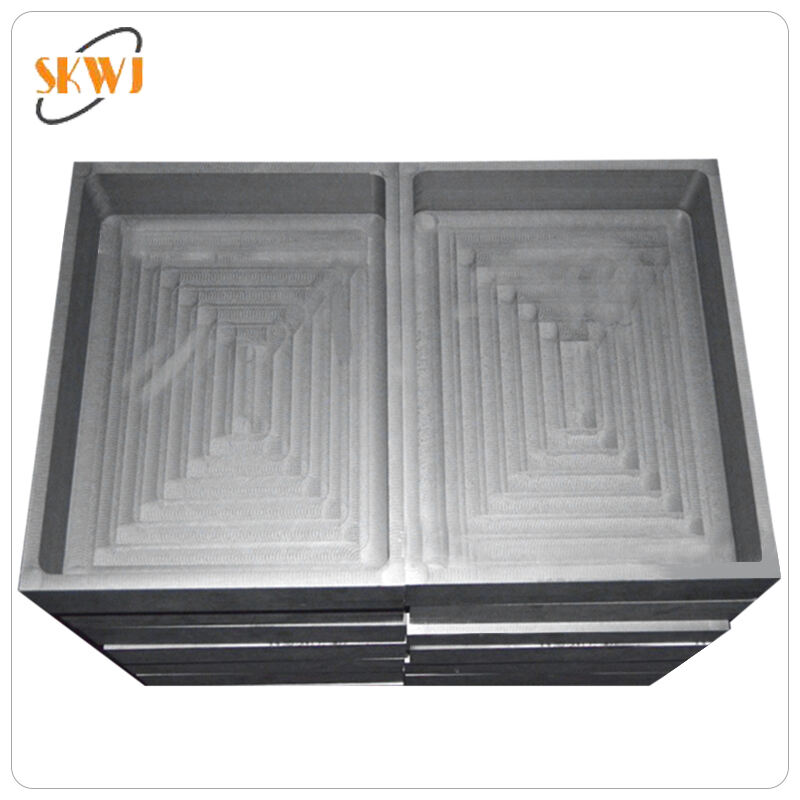

graphite cup made in china

Graphite cups made in China represent a significant advancement in industrial and laboratory equipment manufacturing. These specialized vessels, crafted from high-purity graphite material, offer exceptional thermal conductivity and chemical resistance. The manufacturing process involves precise machining and quality control measures to ensure uniform wall thickness and structural integrity. These cups typically feature a smooth interior surface and can withstand temperatures up to 2000°C, making them ideal for various high-temperature applications. The Chinese manufacturing sector has developed sophisticated techniques for producing these cups, incorporating advanced materials science and engineering principles. The cups come in various sizes and specifications, ranging from small laboratory vessels to larger industrial containers. They exhibit remarkable resistance to thermal shock and maintain dimensional stability under extreme conditions. The graphite material used is carefully selected and processed to minimize impurities, ensuring consistent performance across applications. These cups are particularly valued in metallurgical processes, chemical synthesis, and materials testing laboratories. The manufacturing facilities in China employ strict quality control measures, including detailed material analysis and performance testing, to maintain high standards. Modern production methods allow for customization of dimensions and specifications to meet specific client requirements.