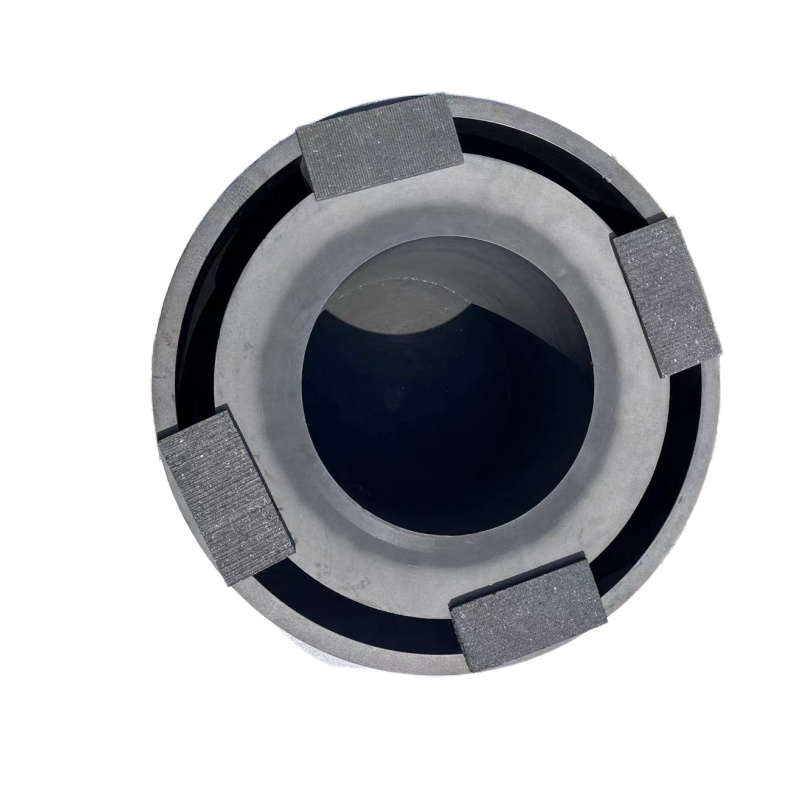

graphite cup for sale

The graphite cup represents a groundbreaking advancement in high-temperature material handling and processing. Crafted from premium-grade graphite, these cups offer exceptional thermal stability and chemical resistance, making them indispensable in various industrial applications. The cup's unique construction features a high-density graphite composition that ensures superior heat conductivity while maintaining structural integrity at temperatures exceeding 2000°C. Each cup undergoes precise machining to achieve optimal dimensional accuracy and surface finish, guaranteeing consistent performance in demanding environments. The graphite cup's non-wetting properties prevent material adhesion, facilitating easy cleaning and maintenance. These vessels are specifically designed for applications in metal casting, semiconductor production, and laboratory research, where precise temperature control and material purity are paramount. The cups feature a carefully engineered wall thickness that balances thermal efficiency with mechanical strength, ensuring reliable performance throughout extended use cycles. Furthermore, their chemical inertness makes them ideal for handling reactive materials without contamination risks, while their excellent thermal shock resistance prevents cracking during rapid temperature changes.