Dəqiq Döküm və Ərimədə Qrafit Kalıplar Necə İstifadə Olunur

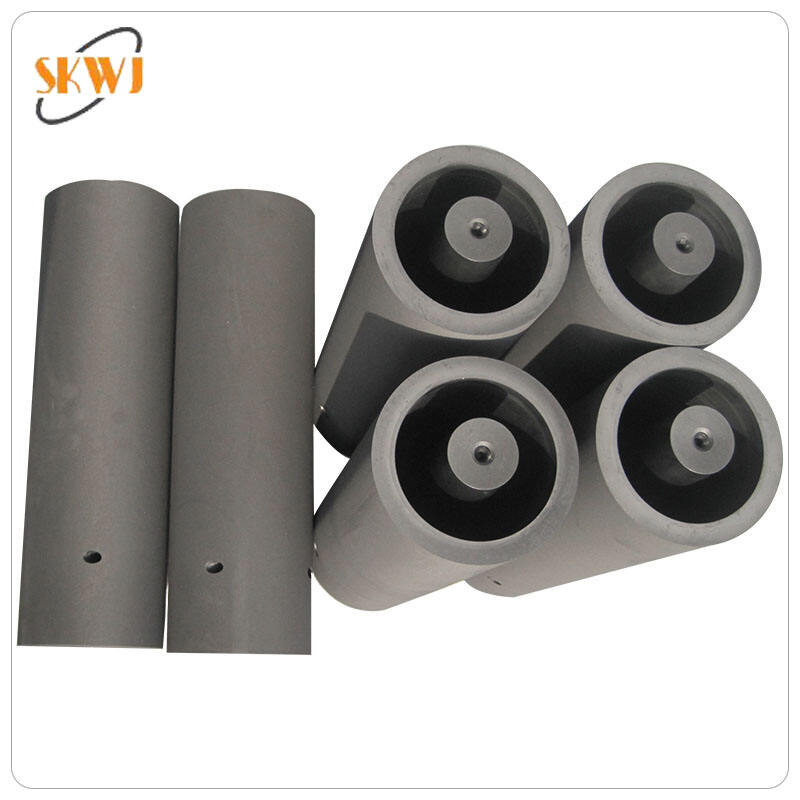

Sənaye istehsalatında inkişaf etmiş materialların birləşdirilməsi yüksək temperatur metallurgiya proseslərinə yanaşma üsulumuzu inqilab halına gətirmişdir. Bu materiallar arasında qrafit kalıp müasir dəqiqlikli tökmə və ərimə əməliyyatlarının əsasını təşkil edir. Fiziki və kimyəvi xüsusiyyətlərinin unikal birləşməsi, ənənəvi qum və ya metal tökmə metodları ilə əldə etmək nəzərəçarpacaq dərəcədə çətin olan, mürəkkəb konfiqurasiyalı detalların hazırlanmasına imkan verir. Qrafit ekstremal istilik şəraitində yüksək struktur möhkəmliyini saxlayır və aşağı istilik genişlənmə əmsalına malik olduğu üçün soyuma fazası boyu tökülən hissənin son ölçülərinin sabit qalmasını təmin edir. Bu sabitlik hava kosmik sənayesi, elektronika və zərgərlik kimi sahələrdə xüsusilə vacibdir, burada mikroskopik bir meyl belə iş prinsipinin pozulmasına və ya əhəmiyyətli material tullantılarına səbəb ola bilər.

Bu yüksək dəqiqlikli mühitdə qrafit kalıbın səmərəliliyi onun özündən yağlanması təbiəti və yüksək istilik keçiriciliyinə məxsusdur. Bir çox digər odadavamlı materiallardan fərqli olaraq, qrafit əksərəkən maye metallarla asanlıqla islanmır, yəni maye metal səth üzərində yapışmadan hamar axır. Bu xüsusiyyət bərkimiş hissənin asan çıxarılmasını asanlaşdırır və kalıbın özünün səth defektləri və ya mexaniki zədələnmə riskini azaldır. Bundan əlavə, materialın istiliyi sürətlə yayma qabiliyyəti nəzarətli bərkimə sürətini təmin edir ki, bu metalların dənə strukturunu təkmilləşdirmək üçün vacibdir. Maye ərintinin və karbon əsaslı qurğunun qarşılıqlı təsirini başa düşməklə mühəndislər həm məhsuldarlığı həm də son məhsulun estetik görünüşünü yaxşılaşdırmaq üçün litin dövriyini optimallaşdıra bilərlər.

Yüksək Performanslı Litmə üçün Material Seçimi

Dəqiq tökmə komponentinin keyfiyyəti, metal tökülənə qədər uzun bir müddət əvvəldən başlayır və ilk növbədə forma üçün istifadə olunan qrafitin xüsusi markasının seçilməsi ilə müəyyən olunur. Dəqiq tökmədə yüksək sıxlıqda izostatik qrafit tez-tez üstünlük təşkil edir, çünki bu, bərabər dənə strukturuna və izotrop xassələrə malikdir. Bu bərabərlik qrafit formanın istilik dövriyyəsinə məruz qalarkən bütün istiqamətlərdə bərabər şəkildə genişlənməsini və daralmasını təmin edir ki, bu da daxili çatlamaların və ya səth deformasiyasının yaranmasının qarşısını alır. Doğru sıxlığın seçilməsi həmçinin tökülən hissənin səthi keyfiyyətini təsir edir; qrafitdə daha incə dənə strukturu metalların daha hamar səthi ilə nəticələnir və tez-tez sonradan intensiv emal və ya cilalanma ehtiyacını aradan qaldırır.

Qrafitin təmizlik səviyyəsi, xüsusilə qiymətli metalların və yüksək təmizlik yarımkeçiricilərin əriməsi zamanı kritik əhəmiyyət kəsb edir. Karbon matrisdəki çirkliyin yüksək temperaturda əriyən metalın içərisinə keçməsi mümkündür və bu, son məhsulun elektrik və mexaniki bütövlüyünü zəiflədən çirklənməyə səbəb olur. Xüsusi təmizləmə prosesləri külli miqdarını bir milyonda 50-dən az səviyyəyə qədər azalda bilər ki, bu onu ən həssas vakuum ərimə tətbiqetmələri üçün yararlı hala gətirir. qrafit forma bu səviyyədəki material mühəndisliyi istehsalçılara yüksək keyfiyyətli litmə evlərinin standart litmə fabriklərindən fərqlənməsini təmin edən, hər bir dəstənin ciddi keyfiyyət standartlarını təmin etməsini imkan verən ardıcıl nəticə əldə etmə imkanı verir.

Həddindən artıq istilik təzyiqi altında struktur bütövlük

Ərimə və tökmədə baş verən əsas problemlərdən biri, minlərlə dərəcə istiliyə malik maye metalın forma səthi ilə qarşlaşdığı zaman yaranan böyük temperatur gradientlərini idarə etməkdir. Qrafit forma bu iş üçün xarakterik olaraq yüksək istilik təzyiqinə davamlılığı səbəbiylə uyğundur. Bir çox keramik materiallar ərimiş polad və ya qızla qarşılaşdıqda parçalanır, lakin qrafitin kristal quruluşu istilik enerjisini səmərəli şəkildə udur və paylayır. Bu möhkəmlik tökmə sürətini artırmağa və dövrlərin qısalmasına imkan verir, çünki qrafit forma investisiya tökməsi və ya daimi polad formalarda tələb olunan geniş miqyaslı qızdırılma mərhələlərinə ehtiyac duymur.

Konstruktiv bütövlüyün saxlanması həm də yüksək temperaturda karbon əsaslı materiallarda aşınmanın əsas səbəbi olan oksidləşməyə müqavimət tələb edir. Bir çox dəqiq ərimə qurğularında qrafit kalıbın xidmət müddətini uzatmaq üçün qoruyucu atmosferlər və ya vakuum kameradan istifadə olunur. Oksigensiz mühitdə işlədikdə qrafit formasını və möhkəmliyini itirmədən $3000^\circ C$ dən yuxarı temperaturlara dözə bilir. Bu xüsusiyyət, mayeləşdirmək üçün son dərəcə yüksək istiliyin tələb olunduğu atəsdən çıxmayan metal komponentlərin və xüsusi ərintilərin istehsalı üçün vacibdir. Materialın natural istilik xüsusiyyətləri ilə soyuma sürətinin balanslaşdırılması ilə istehsalçılar daralma boşluqları və ya qaz porozlığının kimi yayılmış defektləri maneə törədə bilər.

Davamlı və Mərkəzdənqaçan Quruyağına Tətbiqlər

Qrafit kalıbın çoxtərəfli tətbiqi sabit tökmədən kənar, davamlı və mərkəzdənqaçma tökmə kimi daha mürəkkəb avtomatlaşdırılmış proseslərə qədər uzanır. Bu hallarda kalıp metalın maye və bərk halı arasında dinamik interfeys rolunu oynayır. Mis, latun və alüminium kimi rəngli metalların davamlı tökməsində kalıp sistemin içindən çəkilən sim, çubuq və ya borunun formasını müəyyənləşdirir. Qrafitin yüksək istilik keçiriciliyi bu prosesin hərəkətverici qüvvəsidir və metalın tam tələb olunan sürətlə istiliyini çıxararaq, maye nüvənin çərəsini dəstəkləyə biləcək bərk "dəri"nin yaranmasına şərait yaradır.

Rəngli Çubuqların və Boruların Dəqiq İstehsalı

Mis ərintilərinin davamlı tökülərək alınmasında qrafit kalıp əsas istilik mübadiləsi vasitəsi kimi xidmət edir. Ərimiş metal kalıba daxil olarkən, profilini saxlamaq üçün kifayət qədər sürətlə bərkiməlidir, lakin daxili gərginliyi yaratmamaq üçün eyni zamanda çox tez də bərkməməlidir. Qrafitin sürtünmə əmsalı aşağı olduğu üçün bərkimiş metal minimal müqavimətlə kalıbdan çıxarıla bilər. Bu, çəkici avadanlıqlara düşən mexaniki yükü azaldır və çubuqların və ya boruların səthində zədələnməsinin qarşısını alır. Kalıbın daxili ölçülərinin dəqiqliyi məhsulun xarici diametrini birbaşa təyin edir və nəticədə son spesifikasiyalara olduqca yaxın yarımfabrikatların istehsalına imkan verir.

Əlavə olaraq, davamlı quruluşlarda qrafit kalıbın xidmət müddəti xərclərin səmərəli olması baxımından əhəmiyyətli amildir. Hərçənd hərəkət edən metalın sürtünməsi nəticəsində daxili səth zamanla aşınır, lakin yüksək möhkəmlikli sintetik qrafitdən istifadə edilməsi ilə kalıb dəyişdirilmədən minlərcə metr material istehsal etmək mümkündür. İstehsalçılar tez-tez qrafidin aşınmaya davamlılığını daha da artırmaq və istehsal prosesində ölçülərin dəqiqliyinin mikron dəqiqliyi ilə saxlanmasını təmin etmək üçün xüsusi örtüklərdən və ya səth emal üsullarından istifadə edirlər. Bu səviyyədə etibarlılıq qrafiti yüksək həcmli qara olmayan metalların istehsalında sənaye standartına çevirir.

Simmetrik hissələrin mərkəzdənqaçma üsulu ilə tökülməsində üstünlüklər

Mərkəzdənqaçma qüvvəsi ilə lehimləmə, molten metalı kalıpın daxili divarlarına qarşı paylamaq üçün fırlanma qüvvəsindən istifadə edir və bu prosesdə qrafit kalıbdan istifadə boş silindrik detalların istehsalı üçün xarakterik üstünlüklər təqdim edir. Qrafitin yüksək möhkəmlik-ağırlıq nisbəti kalıbın mərkəzdənqaçma yükü altında struktur pozulma riski olmadan yüksək sürətlə fırlanmasına imkan verir. Metal xarici tərəfə doğru itələndikcə, qrafit səth təmiz, reaktiv olmayan bir sərhəd yaradır ki, bu da sıx, çirkabdan təmiz xarici təbəqənin əmələ gəlməsinə səbəb olur. Bu, ağır maşın avadanlığında istifadə olunan yüksək keyfiyyətli laqerlərin, burunquların və halqaların istehsalı üçün xüsusi fayda təqdim edir.

Qrafit kalıbın istilik xassələri burada bir daha əsas rol oynayır, onun sayəsində materialın xaricdən daxilə doğru sürətlə bərkiməsi mümkündür. Bu istiqametli bərkimə, qarışıqları və qaz körpülərini silindrın mərkəzə doğru itələyir, bu mərkəz daha sonra emal edilərək çıxarılır və metallurgik cəhətdən ideal quruluş qalır. Metall kalıbların yüksək sürətlə fırlanma zamanı aşırı qızıb qarşısını almaq üçün mürəkkəb soyuducu qurğulara ehtiyacı ola bilər, qrafitin təbii istiliyi yayma xassəsi tez-tez maşın dizaynını sadələşdirir. Nəticə, statik qravitasiya yayma ilə müqayisədə üstünlükli mexaniki xassələrə malik hissələr əldə etmək üçün daha səmərəli bir tökmə prosesidir.

Qrafitin Vakuumda Ərimə və Təmizləmədəki Rolu

Vakuumda ərimə yarımkeçiricilər sənayesində istifadə olunan xüsusi poladların, superleğirlərin və yüksək təmizlikdə metalların istehsalı üçün kritik prosesdir. Bu nəzarət olunan mühitdə qrafit kalıp həm konteyner, həm də kimyəvi saflaşdırma prosesinin asanlaşdırıcısı kimi iki funksiya yerinə yetirir. Vakuumda ərimə atmosfer qazlarını aradan qaldırdığı üçün kalıp materialının təmizliyi daha da əhəmiyyətli hala gəlir. Yüksək təmizlikdə qrafit vakuum səviyyəsinə təsir göstərə və ya əriyən metalı çirkləndirə biləcək uçucu birləşmələr ayırır, bu da onu təmiz emal mühitini saxlamaq üçün ideal seçim halına gətirir.

Yarımkeçirici Sınıfında Ərimədə Təmizliyin Artırılması

Günəş hüceyrələri və elektron çiplərin istehsalında qrafit kalıp ərimə və soyuma fazaları zamanı ingotları formalaşdırmaq üçün istifadə olunur. Bu sahədə təmizlik tələbləri sənayenin hər hansı bir sahəsində ən yüksək səviyyədə olanlardan hesab olunur. Qrafitdəki hər hansı metal qarışıqları silikona keçə bilər və onun elektrik effektivliyini kəskin şəkildə azalda bilər. Nəticədə, bu kalıplar intensiv kimyəvi təmizləmədən keçirilir və tez-tez karbonla əriyən silikon arasına tam maneə yaratmaq üçün silisium karbiddən (SiC) kimi materiallarla örtülür. Bu, nəticədə alınan kristal strukturun mümkün qədər mükəmməl olmasını təmin edir.

Qrafit kalıp həmçinin ərimə üzərində bərabər temperatur paylanmasını əldə etməyə kömək edir. Yarımkeçiricilərin istehsalında, istiliyin qradiyentləri kristik həyəcanlarda zədələrə səbəb ola bilər və materialı işlənməz hala salar. Qrafitin yüksək emissivliyi və istilik keçiriciliyi vakuum sobasında qızdırma və soyutma dövrlərinə dəqiq nəzarət etməyə imkan verir. Bu parametrləri dəqiq tənzimləyərək, istehsalçılar müasir elektronika sənayesinin əsasını təşkil edən böyük, yüksək keyfiyyətli ingotlar yetişdirə bilərlər, bu, sadə qrafit komponentin yüksək texnologiya tərəqqisinin əsas elementi olduğunu göstərir.

Aerospace Komponentləri üçün Superleğirlərin Emalı

Turbina qanadları və mühərrik korpusları kimi kosmik texnika komponentləri tez-tez ekstremal mexaniki gərginliyə və yüksək temperaturlara dözə bilən superlehimlərdən tökülmüşdür. Bu lehimlərin əriməsi, əksər metalların yumşalacağı və ya əridiyi temperaturda sabit qala bilən qrafit kalıb tələb edir. Karbon əsaslı kalıp, bu hissələrin kristalların böyüməsinin idarə olunması üçün lazım olan uzun soyuma müddəti ərzində mürəkkəb formalarını saxlamaq üçün lazım olan istilik sabitliyini təmin edir. Bu, metal kristallarının oriyentasiyasının detalin son gücünə görə kritik önəm daşıdığı tək kristal tökmə üçün xüsusilə vacibdir.

Bu kontekstdə qrafit kalıbın dəqiq kompleks həndəsi formalara emal oluna bilməsi böyük üstünlükdür. Nömrəli idarəetmə (CNC) vasitəsilə qrafit blokun daxilinə mürəkkəb soyutma kanalları və aerodinamik profillər yaratmaq mümkündür. Bu səviyyədəki detallar tökmə zamanı superleğvə ötürülür və nəticədə minimal son emal tələb edən demək olar ki, son forma yaxın komponent alınır. Ənənəvi keramik investisiya tökməyə nisbətən qrafitdən istifadə aviasiya və enerji istehsalında istifadə olunan təhlükəsizlik üçün kritik olan komponentlərdə daha yaxşı ölçülü təkrarlanmanı və daha təmiz səth emalını təmin edə bilər.

Qrafit Avadanlıqların Davamlılığı və Təmiri

Qrafit möhkəm bir material olsa da, onun təzyiqli tökmə mühitində xidmət müddəti, əsasən, onun necə idarə edildiyi və saxlandığından asılıdır. Qrafit kalıp keyfiyyətə investisiyadır və hər detala düşən ümumi xərclərin azaldılması üçün işlədilmə müddətinin maksimuma çatdırılması vacibdir. Qrafita əsas düşmən oksidləşmədir ki, bu da material havaya $400^\circ C$ -dən yuxarı temperaturda məruz qalanda baş verir. Buna görə də, tökmə sisteminin layihəsi kalıbı mühafizə etmək üçün inert qazla təmizləmə və ya kalıb atmosferə açılmazdan əvvəl temperaturu aşağı salan sürətli soyutma ardıcıllığı kimi tədbirləri nəzərdə tutmalıdır.

Kalıp Xidmət Müddətini Uzatmaq Üçün Ən Yaxşı Təcrübələr

Qrafit kalıbın istifadə müddətini uzatmaq üçün operatorlar materialın hesablanmış hədlərindən kənara çıxan mexaniki təsir və istilik şokunu minimuma endirməyə diqqət yetirməlidirlər. Qrafit istilik şokuna davamlı olsa da, ekstremal və lazım olmayan temperatur dalğalanmaları nəticədə mikro çatlamalara səbəb ola bilər. Su buxarının qrafitin por strukturuna zərər verə biləcəyi üçün, havadan udulmuş qalıq rütubəti aradan qaldırmaq üçün kalıbın tədricən qızdırılması tez-tez tövsiyə olunur. Bundan əlavə, qrafit təbii şəkildə yapışmayan olsa da, uyğun kalıp buraxma agentlərindən istifadə etmək detalların çıxarılması zamanı sürtülməni daha da azalda və kalıp səthini aşındırıcı ərintilərdən qoruya bilər.

Yanmaq, texniki baxımda tez-tez nəzərə alınmayan bir aspektdir. Qrafit göyüdür və yağlar, nəmlik və işxananın mühitindən gələn çirkləndiriciləri udmağa meyllidir. Forma qızdırıldıqda, bu maddələr səthdə çuxurlar yarada və ya əriməyə çirkləndirə bilər. Qrafik formasını təmiz, quru yerlərdə və ya nəzarətli atmosferli kabinetdə saxlamaq növbəti istehsal dövrləri üçün onun hazırdığını təmin edir. Bu protokolları izləməklə, litseylər tək bir forma ilə həyata keçirilə bilən töklərin sayını əhəmiyyətli dərəcədə artıraraq istehsalın son nəticəsinə birbaşa təsir edə bilərlər.

İstifadə edilmiş formaların təmiri və yenilənməsi

Bir neçə dəfə istifadədən sonra məhv olan bəzi keramik kalıplardan fərqli olaraq, qrafit kalıbın istifadə müddətini uzatmaq üçün onu tez-tez təmir etmək mümkündür. Əgər kalıbın səthi ərimiş metal axını nəticəsində xətlənmiş və ya yüngül eroziyaya uğramışsa, tez-tez onu orijinal görünüşünü bərpa etmək üçün yenidən emal etmək və ya cilalamaq olar. Bu, ağır ingot və ya kütüklərin istehsalında istifadə olunan böyük kalıblar üçün xüsusi ilə sərfəlidir. Son məhsulun icazə verilən ölçülər həddində daxilində qalırsa, bir qrafit blokunu bir neçə dəfə təkrar istifadə etmək mümkündür.

Bəzi hallarda kiçik çatlar və ya yaraları bərpa etmək üçün xüsusi qrafit sementlərindən istifadə edilə bilər, lakin bu ümumiyyətlə kalıbın kritik olmayan sahələri üçün nəzərdə tutulur. Avadanlıqları dəyişdirmək və ya təmir etmək qabiliyyəti qrafiti, köməkçi maşınlarla işlənməsi çox çətin və əvəz etmək üçün daha bahalı olan polad və ya mis kimi daimi metal kalıblardan daha çevik bir seçim halına gətirir. Bu uyğunlaşma bacarığı istehsalçıların dizaynlarını daha tez təkmilləşdirməsinə imkan verir və qrafit kalıbı həm tədqiqat və inkişaf, həm də yüksək həcmli istehsal üçün ən sevilən seçim halına gətirir.

SSS

Qrafit kalıbdan metal kalıba nisbətən istifadənin əsas üstünlükləri nələrdir?

Qrafit kalıb bir neçə əsas üstünlüyə malikdir: ekstrem temperaturlarda daha yüksək termal sabitlik, üstün termal şok müqaviməti və aşağı istilik genişlənmə əmsalı. Metal kalıbların əksinə, qrafit $1000^\circ C$-dən yuxarı temperaturlara məruz qaldıqda formalını itirmir və möhkəmliyini itirmir. $1000^\circ C$ , bu onu yüksək ərimə nöqtəsinə malik metalları ərimək üçün ideal edir. Bundan əlavə, qrafitin özü-laylanma və rütubət olmama xassələri ağır örtüklərə ehtiyac olmadan hissələrin daha asan çıxarılmasını və daha yaxşı səth emalını təmin edir.

Qrafit kalıp bir neçə tökmə dövrləri üçün təkrar istifadə edilə bilərmi?

Bəli, qrafit kalıblar xüsusən davamlı tökmə və vakuumda ərimə üçün çoxlu istifadəyə uyğunlaşdırılıb. Dövrlərin sayı tökmə temperaturuna, tökülən metalə və oksigenin mövcudluğuna görə dəyişir. İnert və ya vakuum mühitdə qrafit kalıp yüzlərlə, hətta minlərlə dövrlər davam edə bilər. Bununla belə, açıq hava şəraitində oksidləşmə nəticəsində kalıp sonradan aşınır və ölçülər toleransdan artıq keçdikdə əvəzlənməsi və ya bərpası tələb olunur.

Hansı metallar qrafit kalıbda tökməyə ən uyğundur?

Qrafit kalıblar istisnai dərəcədə çox yönlüdür və qızıl, gümüş, mis, alüminium və bürünc kimi rəngli metallar üçün geniş istifadə olunur. O, habelə şaquli dəmirin və bəzi xüsusi ərintilərin tökülməsi üçün standartdır. Qrafit kimyəvi təsirə qarşı yüksək müqavimət göstərdiyi üçün yarımkeçirici səviyyəli silisium və çirklənmənin qarşısının alınmasının ən vacib prioritet olduğu digər qiymətli metalların safləşdirilməsi kimi yüksək saflıqlı tətbiqlər üçün üstünlük təşkil edir.

Qrafitin porozluğu tökmə keyfiyyətinə necə təsir edir?

Qrafit kalıbın mayezi tökmə prosesində qaz idarə edilməsinə təsir edir. Müəyyən səviyyədə mayezi, həbs olunmuş havanın və qazların kalıb materialı vasitəsilə çıxmasını təmin edərək metal hissədə kovuqların və mayezi riskini azaldır. Bununla belə, əgər qrafit çox mayezi olarsa, mərtəb metallar səthə nüfuz edə bilər, bu isə səthi pürçəkli hala gətirər və ya hissəni çıxarmağı çətinləşdirər. Buna görə, ventilyasiya ilə səth keyfiyyəti arasında istədiyimiz balansı əldə etmək üçün doğru qrafit sıxlığı və dərəcəsini seçmək vacibdir.