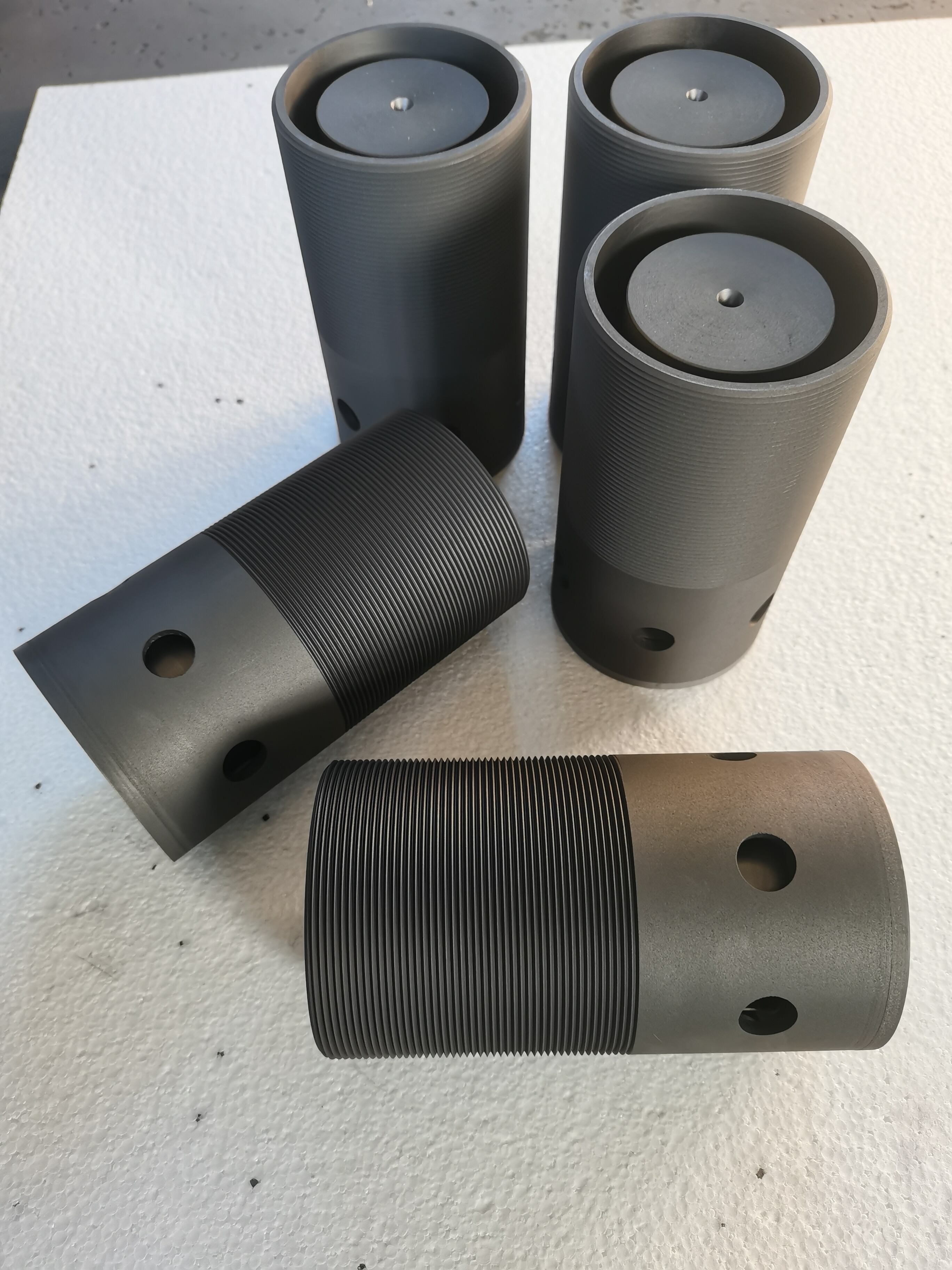

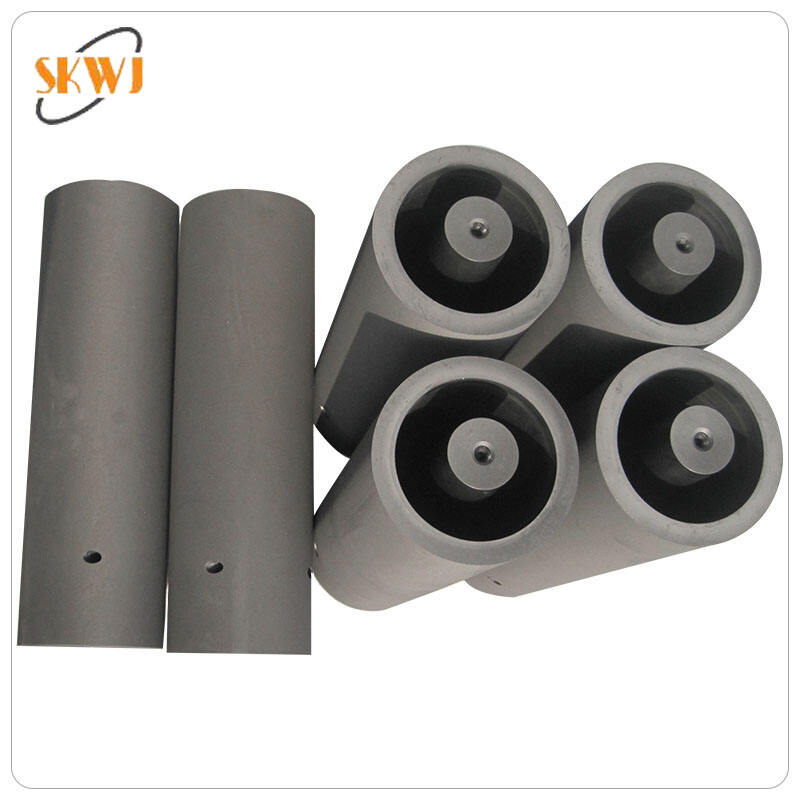

natural graphite made in china

Natural graphite made in China represents a cornerstone material in modern industry, distinguished by its exceptional thermal and electrical conductivity properties. China leads global graphite production, accounting for over 70% of the world's supply, with deposits primarily concentrated in Heilongjiang, Shandong, and Inner Mongolia regions. The material exists in three primary forms: flake, amorphous, and vein graphite, each carefully extracted and processed to meet diverse industrial specifications. Chinese natural graphite undergoes sophisticated purification processes to achieve carbon content levels exceeding 99.95%, making it ideal for high-performance applications. The material's unique crystalline structure provides superior lubricating properties, high thermal resistance up to 3,000°C, and excellent chemical stability. These characteristics make it essential in various applications, from lithium-ion battery anodes to refractory materials and lubricants. The production process involves advanced flotation techniques, chemical purification, and precise particle size control, ensuring consistent quality and performance. Chinese manufacturers employ state-of-the-art processing technologies to enhance the material's purity and optimize its physical properties for specific applications.