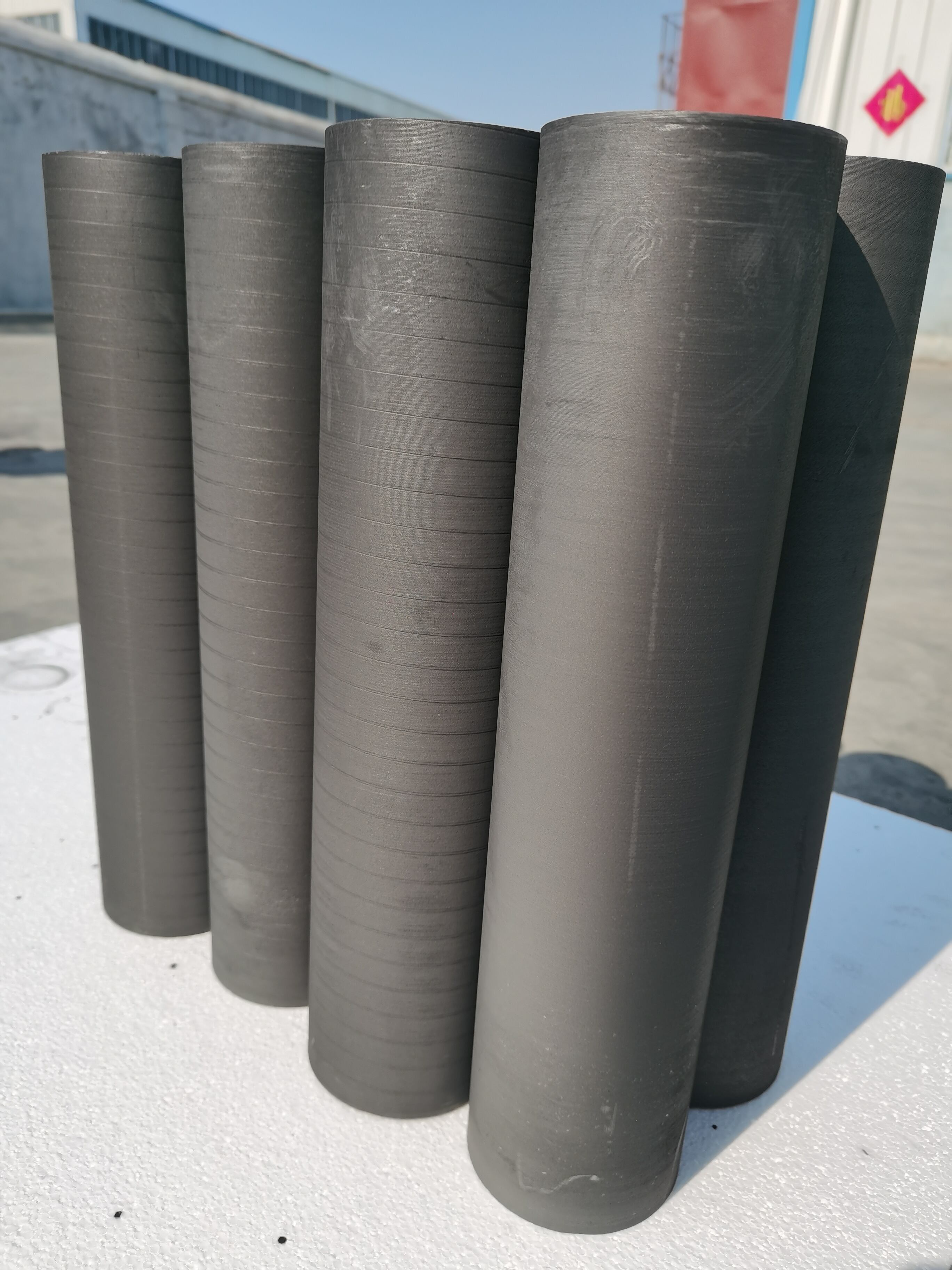

graphite slabs

Graphite slabs represent a cornerstone material in various industrial applications, combining exceptional thermal conductivity with remarkable mechanical strength. These engineered components are manufactured through a sophisticated process that involves high-temperature treatment and precise molding techniques, resulting in dense, uniform structures with consistent properties throughout. The slabs feature a unique crystalline structure that enables superior heat distribution and electrical conductivity, making them invaluable in numerous high-performance applications. These versatile components can withstand extreme temperatures up to 3,000°C in non-oxidizing environments, showcasing their robustness in demanding conditions. The material's low coefficient of thermal expansion ensures dimensional stability during temperature fluctuations, while its chemical inertness provides resistance against most acids and alkalis. Modern graphite slabs incorporate advanced manufacturing techniques that allow for precise control over porosity, density, and grain size, enabling customization for specific applications. From metallurgical processing to semiconductor manufacturing, these slabs serve as essential components in furnaces, heat exchangers, and various industrial equipment. Their self-lubricating properties and excellent machinability further enhance their utility across different sectors.