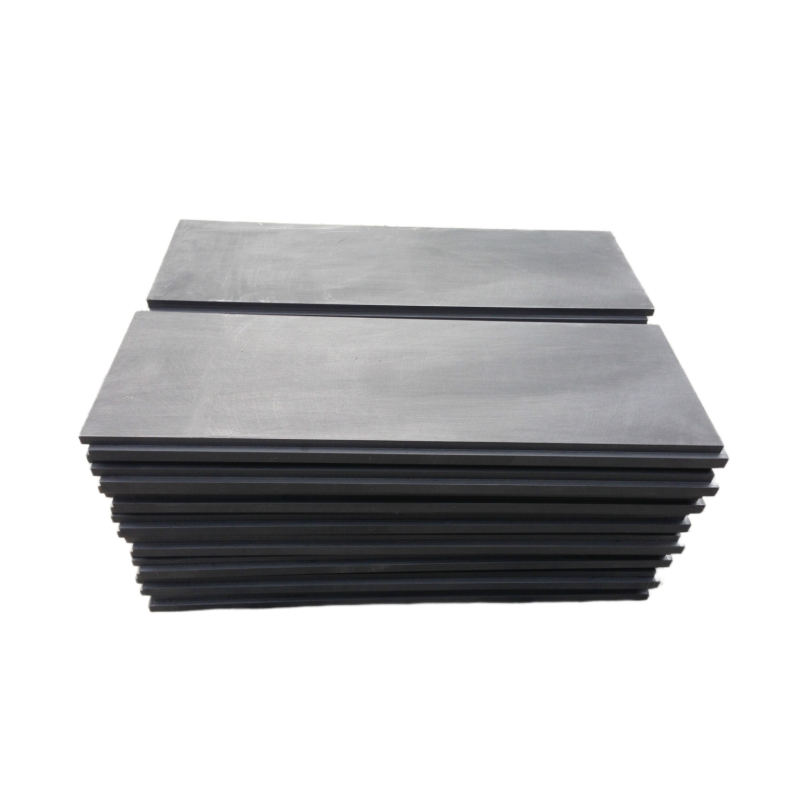

graphite coin mold

A graphite coin mold represents a sophisticated tool designed specifically for precision coin manufacturing and numismatic applications. This specialized equipment utilizes high-quality graphite material, known for its exceptional heat resistance and dimensional stability, to create detailed and accurate coin impressions. The mold consists of two precisely machined graphite plates that form the obverse and reverse designs of the coin. The material's natural properties allow for intricate detail retention while maintaining structural integrity through multiple casting cycles. These molds feature carefully engineered venting systems to ensure proper metal flow and prevent defects during the casting process. The graphite composition offers excellent thermal conductivity, enabling rapid heating and cooling cycles which significantly enhance production efficiency. Modern graphite coin molds often incorporate advanced surface treatments that extend their operational lifespan and improve release characteristics. The design typically includes alignment pins and registration marks for precise mold matching, ensuring consistent quality across production runs. These molds are compatible with various precious metals, including gold, silver, and platinum, making them versatile tools for both commercial minting operations and artisanal coin production.