graphite blocks suppliers

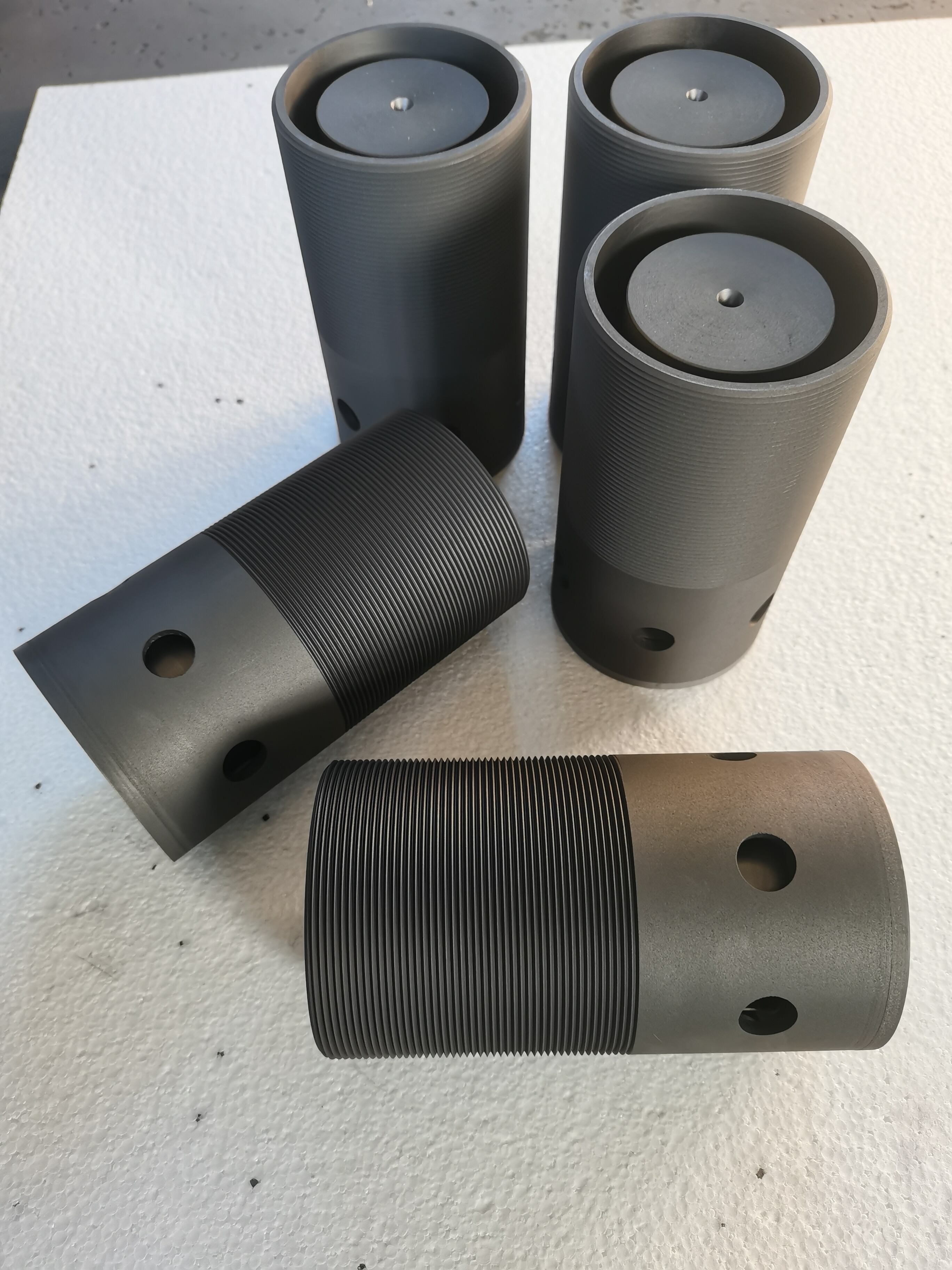

Graphite blocks suppliers play a crucial role in various industrial applications, providing high-quality carbon-based materials essential for numerous manufacturing processes. These suppliers specialize in producing and distributing graphite blocks that offer exceptional thermal conductivity, chemical resistance, and structural stability. The blocks are manufactured through sophisticated processes that ensure consistent quality and precise specifications, making them ideal for applications in metallurgy, semiconductor production, and nuclear power generation. Modern graphite blocks suppliers utilize advanced production techniques to create products with varying densities, sizes, and grades to meet specific industry requirements. They employ strict quality control measures throughout the manufacturing process, from raw material selection to final product inspection. These suppliers often provide customization options, allowing clients to obtain graphite blocks tailored to their exact specifications, including specialized treatments for enhanced performance characteristics. The suppliers maintain extensive inventory systems and efficient distribution networks to ensure reliable product availability and timely delivery to customers worldwide.