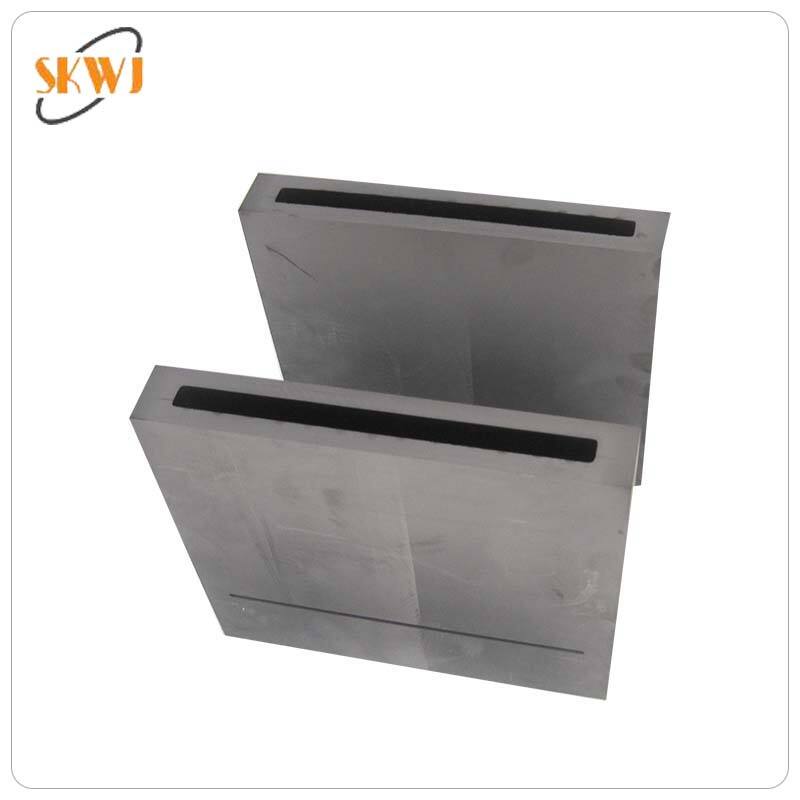

black graphite ring

The black graphite ring represents a significant advancement in industrial sealing technology, combining durability with exceptional performance characteristics. This innovative component is engineered using high-purity graphite material, processed through advanced manufacturing techniques to achieve a distinctive black finish that enhances its wear resistance. The ring's unique composition allows it to maintain structural integrity under extreme temperatures, ranging from -200°C to 800°C, making it ideal for demanding industrial applications. Its self-lubricating properties significantly reduce friction, leading to improved equipment longevity and reduced maintenance requirements. The black graphite ring's chemical inertness makes it particularly valuable in corrosive environments, while its low coefficient of thermal expansion ensures dimensional stability across varying operating conditions. These rings are precision-engineered to provide reliable sealing solutions in rotating equipment, pumps, and compressors, where traditional sealing materials might fail. The material's inherent porosity is carefully controlled during manufacturing, resulting in a product that offers excellent gas impermeability while maintaining its structural strength. This combination of properties makes the black graphite ring an essential component in industries ranging from petrochemical processing to power generation, where reliability and performance are paramount.